Single Epoxy

H907-S贴片红胶,SMT红胶快速固化,电子贴片胶水,单组份环氧胶固定胶水

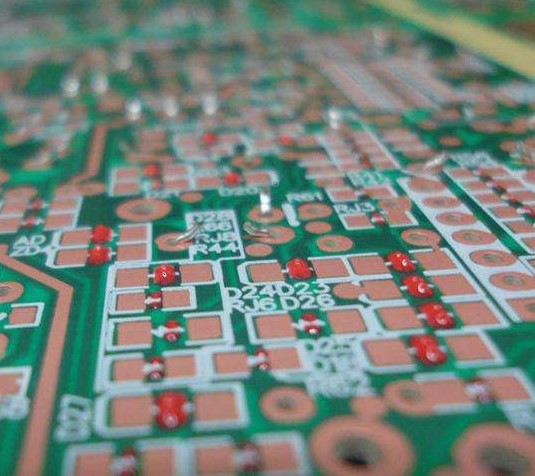

本品系SMT 专用的单组份热固化环氧树脂胶粘剂,具有

1.贮存稳定,使用方便

2.快速固化,强度好

3.触变性好,电气绝缘性能好等特点。

本品主要用于片状电阻、电容、IC 芯片及其它电子元件的的贴装工艺,适用于点胶和刮胶。

特征

粘稠红色膏状体 比重(25℃) 1.25-1.35 粘度 (25℃)35,000-55,000 cps

保存期限:25度15天 5度2个月

①、容许低温度硬化;

②、尽管超高速涂敷,微少量涂敷任可保持没有拉丝,塌陷的稳定形状;

③、对于各种表明粘着零件,都可获得安定的粘着强度;

④、储存安定性能优良;

⑤、具有高耐热性和优良的电气特性;

⑥、也可用于印刷。

硬化条件

120度15-20分钟或130-150度5-10分钟

○ 硬化温度越高、而且硬化时间越长,越可获得高度着强度;

○ 依装着于基板的零件大小,及装着位置的不同,实际附加于接着剂的温度会变化,因此需要找出最适合的硬化条件。

This product is a one component heat curing epoxy resin adhesive for SMT, with

1. Stable storage and convenient use

2. Fast curing, good strength

3. Good thixotropy and electrical insulation.

This product is mainly used for laminating process of sheet resistor, capacitor, IC chip and other electronic components, suitable for dispensing and scraping.

features

Viscosity red paste specific gravity (25 ℃) 1.25-1.35 viscosity (25 ℃) 35000-55000 CPS

Shelf life: 25 ° 15 days, 5 ° 2 months

① . allow low temperature hardening;

② Even though the coating is ultra-high speed, a small amount of coating can keep the stable shape without drawing and collapse;

③ For all kinds of adhesive parts, stable adhesive strength can be obtained;

④ Good storage stability;

⑤ , with high heat resistance and excellent electrical characteristics;

⑥ , can also be used for printing.

Hardening conditions

120 ° 15-20 minutes or 130-150 ° 5-10 minutes

The higher the hardening temperature and the longer the hardening time, the higher the strength can be obtained;

According to the size of the parts installed on the substrate and the different installation positions, the actual temperature of the additive will change, so it is necessary to find out the most suitable hardening conditions.

related articles

- H907-TP-8, Type-c adhesive, Type-c connector sealant, sealing adhesive, epoxy resin adhesive

- H907-500, magnetic adhesive, electromagnetic shielding adhesive, single component epoxy adhesive

- H907-DH, single component thermal conductive epoxy adhesive, thermal conductive adhesive, adhesive

- H907-C-2, conductive adhesive, transformer conductive adhesive, conductive carbon adhesive

- H907-HF-Z, single component elastic epoxy adhesive, transformer column filling adhesive

- H907-HF-1 transformer core adhesive, high-strength epoxy resin adhesive, high-temperature adhesive

- H907-HF single component epoxy resin adhesive, magnetic core adhesive, transformer adhesive

- H907-HF低卤素单组份环氧树脂胶,无卤磁芯胶黑胶灰胶电感胶水epoxy 电机马达胶

Post comments