Epoxy adhesive

What are the advantages and disadvantages of epoxy resin structural adhesive?

Epoxy resin structural adhesive offers several advantages and disadvantages. Here's an overview of its pros and cons:

Advantages of Epoxy Resin Structural Adhesive:

1. High Bonding Strength: Epoxy resin structural adhesive provides excellent bonding strength, allowing for strong and durable bonds between various materials. It can withstand high loads, stresses, and vibrations, making it suitable for structural applications.

2. Versatility: Epoxy resin structural adhesive can bond a wide range of materials, including metals, composites, plastics, ceramics, and more. This versatility makes it a poPUlar choice in various industries, such as automotive, aerospace, construction, and manufacturing.

3. Chemical and Environmental Resistance: Epoxy resin structural adhesive is resistant to chemicals, solvents, moisture, heat, and other environmental factors. It maintains its adhesive strength and performance even in harsh conditions, ensuring the longevity and reliability of the bonded structure.

4. Gap Filling Capabilities: Epoxy resin structural adhesive can fill gaps and irregularities between mating surfaces, ensuring a tight and secure bond. This feature helps to compensate for any imperfections in the surfaces being bonded, enhancing the overall strength and integrity of the assembly.

5. Excellent Adhesion: Epoxy resin structural adhesive exhibits excellent adhesion to various substrates. It chemically reacts with the surface of the materials, creating a strong and durable bond that is resistant to peeling, cracking, or delamination.

Disadvantages of Epoxy Resin Structural Adhesive:

1. Cure Time: Epoxy resin structural adhesive typically requires a curing process, which can take some time. This can slow down production or assembly processes, especially in situations where fast bonding is required.

2. Mixing and Application: Epoxy resin structural adhesive usually requires proper mixing of resin and hardener components before application. The correct ratio and thorough mixing are crucial for achieving optimal bonding performance.

3. Health and Safety Precautions: Epoxy resin structural adhesive may contain chemicals that can be hazardous if not handled properly. Users need to follow safety guidelines, such as wearing protective equipment and working in well-ventilated areas, to minimize health risks.

4. Cost: Epoxy resin structural adhesive can be more expensive compared to other types of adhesives. The higher cost is justified by its superior bonding strength and performance, but it may not be suitable for applications with budget constraints.

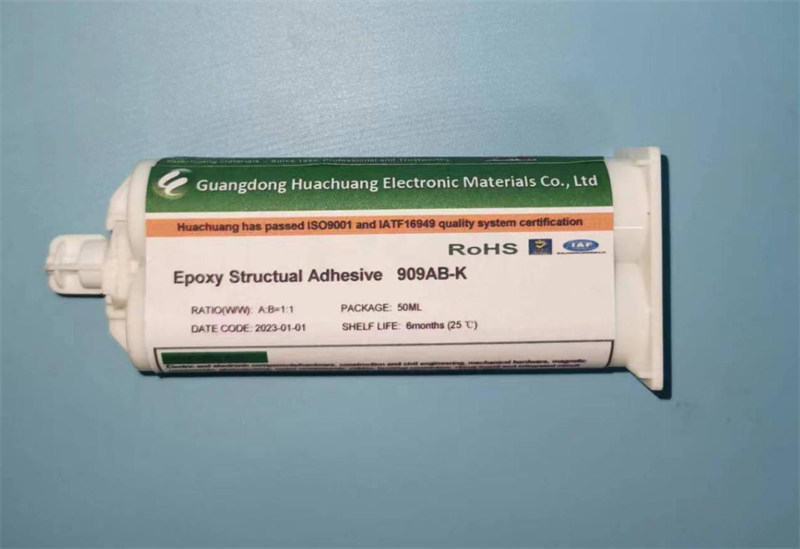

Guangdong Huachuang Electronic Materials Co., Ltd. is a professional adhesive research and development and production enterprise located in Guangdong Province, China. With factories in Guangdong Province, Hunan Province, and Jiangsu Province, China, the company specializes in the formulation and production of various adhesive products, including epoxy resin structural adhesive. Their epoxy adhesive solutions are known for their high quality, reliability, and performance, meeting the diverse requirements of different industries. With a commitment to research and development, production excellence, and customer support, Guangdong Huachuang Electronic Materials Co., Ltd. has established itself as a trusted choice for epoxy adhesive solutions in the market.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments