Epoxy adhesive

What are the differences between epoxy structural adhesive and epoxy AB adhesive?

Epoxy structural adhesive and epoxy AB adhesive are two commonly used types of epoxy adhesives. While they share some similarities, there are also notable differences between them. Let's explore these differences in detail:

1. Composition: Epoxy structural adhesive is a two-component adhesive that consists of a resin and a hardener. It requires the mixing of these components in the correct ratio to initiate the curing process. On the other hand, epoxy AB adhesive, also known as epoxy adhesive with an activator and a base, is a two-component adhesive that consists of an activator and a base. Unlike epoxy structural adhesive, epoxy AB adhesive does not require precise mixing ratios, as the activator and base components are pre-measured and supplied in separate containers.

2. Curing Time: Epoxy structural adhesive typically has a longer curing time compared to epoxy AB adhesive. This longer curing time allows for better positioning and adjustment of the bonded parts before the adhesive fully sets. Epoxy AB adhesive, on the other hand, usually cures relatively quickly, which can be advantageous when there is a need for faster assembly or production processes.

3. Bonding Strength: Epoxy structural adhesive is known for its excellent bonding strength. It provides a strong and durable bond between various substrates, including metals, plastics, and composites. Epoxy AB adhesive also offers good bonding strength, but it may not be as strong as epoxy structural adhesive in certain applications. The specific bonding strength of both adhesives can vary depending on factors such as the substrate materials, surface preparation, and curing conditions.

4. Application Areas: Epoxy structural adhesive is commonly used in applications that require high strength and structural integrity, such as bonding heavy components, load-bearing joints, and structural repairs. It is widely used in industries such as automotive, aerospace, construction, and marine. Epoxy AB adhesive is often used in applications that require fast assembly or repairs, such as bonding small parts, electronics, and general-PUrpose bonding. It is commonly used in industries such as electronics, hobby and crafts, and small-scale repairs.

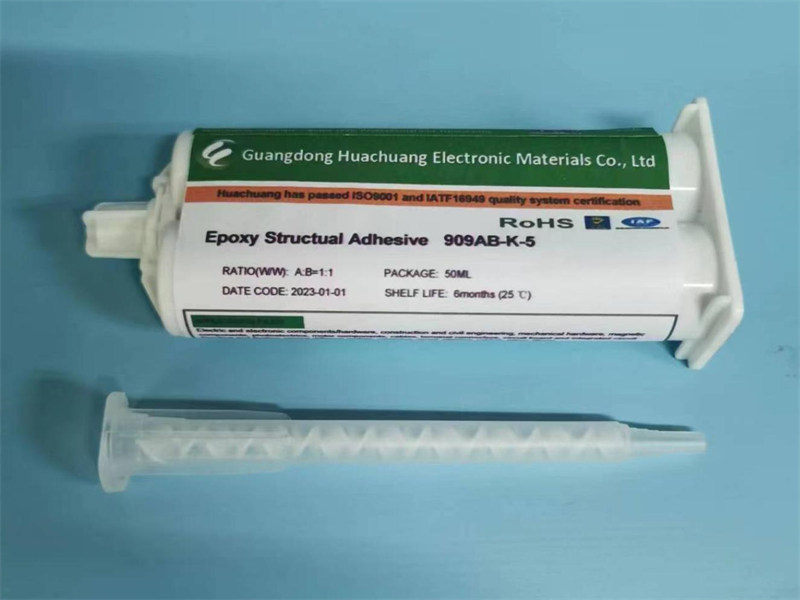

Guangdong Huachuang Electronic Materials Co., Ltd., a professional adhesive research and development and production enterprise located in Guangdong Province, China, offers a wide range of epoxy adhesives, including epoxy structural adhesive and epoxy AB adhesive. With their expertise in adhesive formulation and production, they ensure that their epoxy adhesives provide reliable bonding strength and performance. Their commitment to research, development, and production excellence has made them a trusted choice for adhesive solutions in various industries. With factories in Guangdong Province, Hunan Province, and Jiangsu Province, China, the company is well-equipped to meet the adhesive needs of customers across different regions.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments