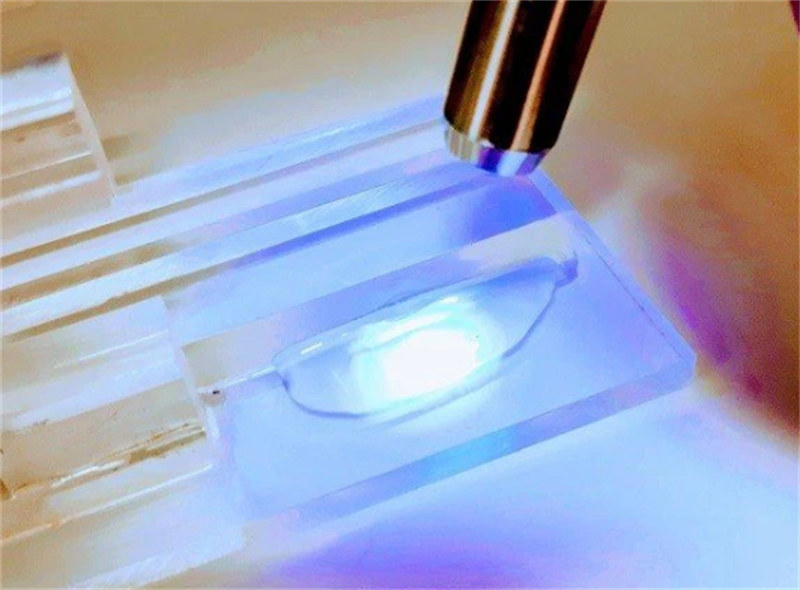

UV adhesive

UV glue: Improving Productivity in Automotive Assembly

as a manufacturer of UV adhesives. Guangdong Huachuang Electronic Materials Co., Ltd. has established itself as a leading provider of high-quality UV adhesives for various industries, including Automotive Assembly.

The automotive industry is constantly evolving, with manufacturers seeking innovative solutions to improve productivity and efficiency in assembly processes. Adhesive technologies play a crucial role in automotive assembly, providing a reliable and efficient method for joining various components. UV adhesives from Guangdong Huachuang Electronic Materials Co., Ltd. offer several advantages over traditional adhesive technologies, making them an ideal choice for automotive assembly.

One of the key advantages of UV adhesives is their rapid curing time. Traditional adhesives often require significant curing time, which can slow down assembly processes and increase production time. UV adhesives, on the other hand, cure rapidly when exposed to ultraviolet light. This allows for faster assembly, as the adhesive quickly solidifies and creates a strong bond between the components. The fast curing time of UV adhesives from Guangdong Huachuang Electronic Materials Co., Ltd. significantly improves productivity in automotive assembly, reducing production time and increasing outPUt.

UV adhesives also offer excellent bonding strength, ensuring a durable and reliable bond between automotive components. The strong bond created by UV adhesives can withstand the rigorous demands of the automotive industry, including temperature fluctuations, vibrations, and exposure to harsh environmental conditions. This makes UV adhesives suitable for a wide range of automotive applications, such as bonding interior trim components, sealing glass windows, and securing electronic modules.

In addition to their bonding strength, UV adhesives from Guangdong Huachuang Electronic Materials Co., Ltd. also offer excellent resistance to temperature extremes. Automotive components are subjected to a wide range of temperatures, from extreme heat to freezing cold. UV adhesives can withstand these temperature variations without compromising their bonding strength or integrity. This ensures that the bonded components remain securely in place, even under challenging conditions, providing long-lasting performance and reliability.

Another advantage of UV adhesives is their versatility in bonding different materials. Automotive assembly often involves joining various materials, such as metal, plastic, and glass. UV adhesives from Guangdong Huachuang Electronic Materials Co., Ltd. are formulated to provide excellent adhesion to a wide range of substrates, making them suitable for bonding different automotive components. Whether it's bonding metal brackets, attaching plastic trim, or sealing glass windows, UV adhesives offer a reliable and versatile solution.

Guangdong Huachuang Electronic Materials Co., Ltd. understands the unique requirements of the automotive industry and has developed a range of UV adhesives specifically tailored for automotive assembly. Their adhesives are designed to meet the stringent quality and performance standards of the automotive industry, ensuring that they can withstand the demanding conditions of automotive applications. Their UV adhesives undergo rigorous testing and quality control measures to ensure consistency and reliability.

Furthermore, Guangdong Huachuang Electronic Materials Co., Ltd. is committed to continuous research and development to stay at the forefront of adhesive technology. They collaborate with automotive manufacturers and industry experts to understand the evolving needs of the automotive industry and develop innovative adhesive solutions. This commitment to innovation allows them to provide cutting-edge adhesive technologies that meet the specific requirements of automotive assembly.

Guangdong Huachuang Electronic Materials Co., Ltd. also prioritizes environmental sustainability in their manufacturing processes. They have implemented measures to minimize waste, reduce energy consumption, and optimize production processes to minimize their environmental impact. Their production facilities adhere to international environmental management standards, reflecting their dedication to responsible manufacturing practices.

In conclusion, UV adhesives from Guangdong Huachuang Electronic Materials Co., Ltd. offer significant benefits for automotive assembly. With their rapid curing time, strong bonding strength, temperature resistance, and versatility in bonding different materials, UV adhesives improve productivity and efficiency in automotive assembly processes. Guangdong Huachuang Electronic Materials Co., Ltd.'s commitment to quality, innovation, and environmental sustainability makes them a trusted partner in the automotive industry.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments