UV adhesive

UV glue: Enhancing Bonding Strength in Aerospace Applications

UV glue, also known as UV adhesive, has emerged as a game-changer in the aerospace industry, offering enhanced bonding strength and reliability for critical applications. One notable player in the field of adhesive research and development is Guangdong Huachuang Electronic Materials Co., Ltd., a leading manufacturer based in Guangdong Province, China. With factories in Guangdong, Hunan, and Jiangsu provinces, the company has been at the forefront of developing and producing UV adhesives since its establishment in 1999.

In the aerospace industry, where safety and performance are of utmost importance, the bonding of various components plays a crucial role. Traditional adhesives have limitations in terms of bonding strength, durability, and compatibility with aerospace materials. However, UV glue has emerged as a viable solution, offering superior performance and reliability.

Guangdong Huachuang Electronic Materials Co., Ltd. has recognized the unique requirements of the aerospace industry and has invested significant efforts in developing UV adhesives that meet these demands. Their UV glue formulations are specifically designed to provide exceptional bonding strength, durability, and resistance to harsh environmental conditions commonly encountered in Aerospace Applications.

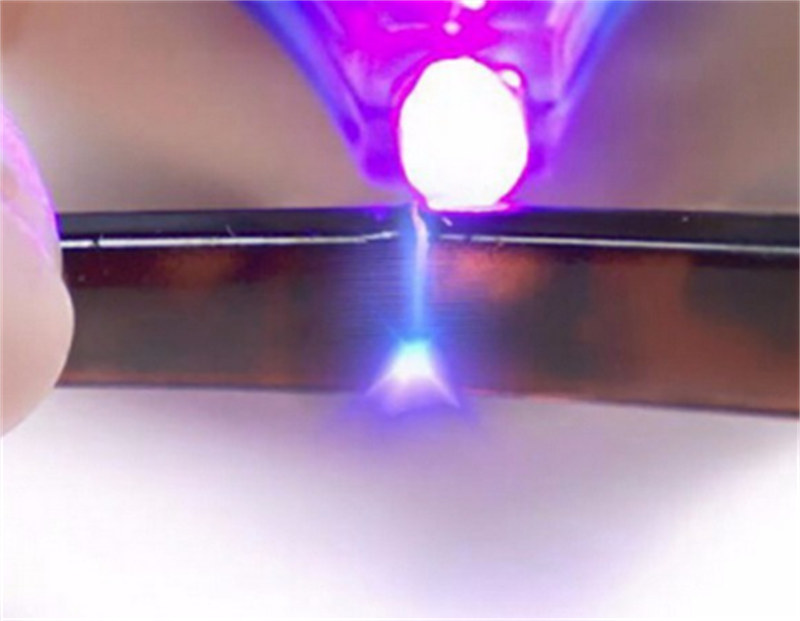

One of the key advantages of UV glue in aerospace bonding is its ability to provide high bond strength. The UV curing process, initiated by exposure to ultraviolet light, allows for rapid and complete curing, resulting in a strong and durable bond. This is particularly crucial in aerospace applications, where components are subjected to extreme forces, vibrations, and temperature fluctuations. Guangdong Huachuang Electronic Materials Co., Ltd. has perfected the formulation of their UV adhesives to ensure excellent bond strength, providing reliable and long-lasting bonding solutions for critical aerospace components.

Furthermore, UV glue offers excellent resistance to various environmental factors encountered in aerospace applications. Aerospace components are exposed to extreme temperatures, humidity, chemicals, and UV radiation. Traditional adhesives may deteriorate or lose their bond strength under such conditions, jeopardizing the integrity of the components. However, Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives that exhibit exceptional resistance to these environmental factors. Their UV glue formulations are engineered to withstand a wide range of temperatures, chemicals, and UV radiation, ensuring the longevity and reliability of bonded aerospace components.

In addition to bond strength and environmental resistance, UV glue also offers advantages in terms of efficiency and ease of use. The UV curing process allows for rapid curing within seconds, significantly reducing assembly time and increasing manufacturing throughPUt. This is particularly beneficial in the aerospace industry, where time-sensitive production is crucial to meet demanding schedules. Moreover, UV glue can be easily applied and cured in a controlled manner, ensuring precise and consistent bonding results. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with optimized viscosity and curing profiles, facilitating easy application and curing in aerospace assembly processes.

The versatility of UV glue is another advantage that makes it suitable for a wide range of aerospace applications. It exhibits excellent adhesion to various materials commonly used in aerospace, including metals, composites, plastics, and glass. This versatility allows for the bonding of different components, regardless of the materials involved. Guangdong Huachuang Electronic Materials Co., Ltd. has conducted extensive research and development to ensure their UV adhesives offer optimized adhesion to aerospace materials, enabling secure bonding and ensuring the overall performance and reliability of aerospace components.

Moreover, UV glue offers a clean and aesthetically pleasing finish, which is particularly important in aerospace applications. The transparent nature of UV adhesives allows for invisible bonding, enhancing the appearance of aerospace components. This is crucial for components that are visible or exposed to passengers, as it contributes to a visually appealing and professional appearance. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with excellent optical clarity, ensuring a seamless finish in aerospace applications.

Guangdong Huachuang Electronic Materials Co., Ltd. is committed to providing high-quality UV adhesives that meet the stringent requirements of the aerospace industry. The company adheres to strict quality control measures and invests in advanced manufacturing facilities to ensure the performance and reliability of their products. They also work closely with aerospace manufacturers to understand their specific needs and develop customized adhesive solutions that meet their unique requirements.

In conclusion, UV glue has emerged as a reliable and high-performance solution for bonding in aerospace applications. Guangdong Huachuang Electronic Materials Co., Ltd., with its extensive experience in adhesive research and development, has played a significant role in advancing the capabilities of UV adhesives for aerospace bonding. Their UV glue formulations offer enhanced bonding strength, environmental resistance, efficiency, versatility, and a visually appealing finish. By leveraging the advantages of UV glue, Guangdong Huachuang Electronic Materials Co., Ltd. contributes to the production of safe, reliable, and high-performance aerospace components.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments