UV adhesive

UV glue: Enabling Miniaturization in Electronics

as a manufacturer of UV adhesives. Guangdong Huachuang Electronic Materials Co., Ltd. has been at the forefront of enabling Miniaturization in the Electronics industry through the development of high-quality UV adhesives.

The electronics industry is constantly evolving, with a growing demand for smaller and more compact devices. This trend towards miniaturization presents unique challenges in terms of bonding and assembly. Traditional adhesives may not offer the precision and reliability required for these small-scale applications. Guangdong Huachuang Electronic Materials Co., Ltd. recognized this need and has developed UV adhesives that are specifically designed to meet the demands of miniaturized electronics.

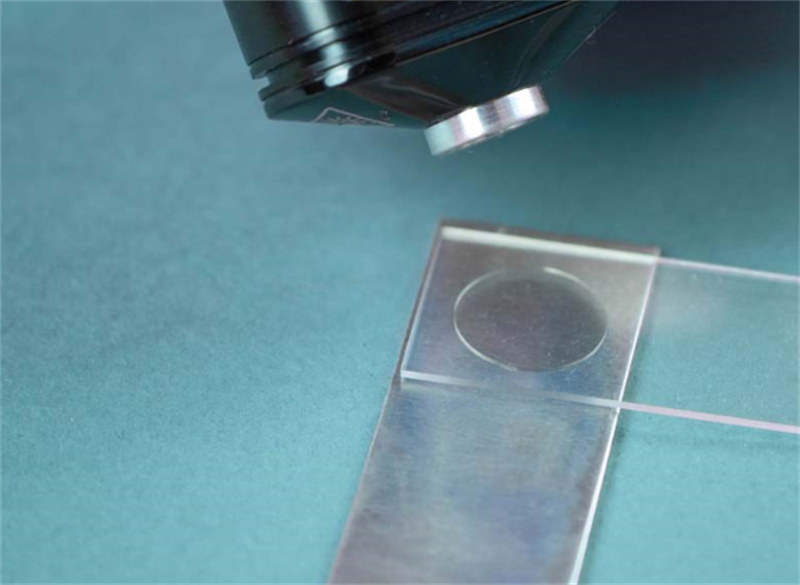

UV adhesives are a poPUlar choice for electronics applications due to their ability to cure quickly and provide strong bonds. They are commonly used in the assembly of electronic components, such as printed circuit boards (PCBs), display panels, sensors, and microchips. Guangdong Huachuang Electronic Materials Co., Ltd. has harnessed the power of UV LED technology to enhance the performance of their UV adhesives and enable miniaturization in the electronics industry.

One of the key advantages of UV adhesives in miniaturized electronics is their ability to provide precise and controlled bonding. The curing process of UV adhesives is initiated by exposure to UV light, which triggers a rapid polymerization reaction. This allows for precise positioning and alignment of components before curing, ensuring accurate and reliable assembly. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with excellent flow properties, enabling them to fill small gaps and provide uniform coverage, resulting in strong and consistent bonds.

Furthermore, UV adhesives offer excellent adhesion to a wide range of substrates commonly used in electronics, including glass, metal, plastic, and ceramic. This versatility allows for the bonding of different materials in miniaturized devices, enabling the integration of various components into a compact form factor. Guangdong Huachuang Electronic Materials Co., Ltd. has conducted extensive research and development to optimize the formulation of their UV adhesives, ensuring compatibility with different substrates and providing reliable bonding solutions for diverse electronic applications.

In addition to precise bonding, UV adhesives also offer other advantages that are particularly beneficial for miniaturized electronics. One such advantage is their low-temperature curing process. Unlike traditional adhesives that require high temperatures for curing, UV adhesives cure at room temperature or with the application of UV light. This low-temperature curing is crucial for delicate electronic components that may be sensitive to heat. It allows for the assembly of temperature-sensitive devices without the risk of damage or degradation.

Moreover, UV adhesives provide excellent electrical insulation properties, which are essential for electronic devices. They offer high dielectric strength and low electrical conductivity, ensuring the integrity and performance of electronic circuits. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with superior electrical insulation properties, allowing for the reliable bonding and protection of sensitive electronic components.

Another significant benefit of UV adhesives in miniaturized electronics is their ability to create a visually appealing finish. The transparent nature of UV adhesives allows for invisible bonding, enhancing the aesthetics of electronic devices. This is particularly important for applications such as display panels, where a clear and seamless appearance is desired. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with excellent optical clarity, ensuring a visually pleasing finish in miniaturized electronic devices.

Guangdong Huachuang Electronic Materials Co., Ltd. is committed to delivering high-quality UV adhesives that meet the specific requirements of the electronics industry. They invest in advanced manufacturing facilities and employ stringent quality control measures to ensure the performance and reliability of their products. The company also offers customized adhesive solutions, working closely with their customers to understand their unique needs and develop adhesives that deliver optimal results.

In conclusion, Guangdong Huachuang Electronic Materials Co., Ltd. has been instrumental in enabling miniaturization in the electronics industry through their high-quality UV adhesives. These adhesives offer precise bonding, excellent adhesion to diverse substrates, low-temperature curing, superior electrical insulation properties, and visually appealing finishes. By leveraging the advancements in UV LED technology, Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives that meet the demands of miniaturized electronics and contribute to the development of smaller and more advanced electronic devices.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments