UV adhesive

UV Adhesives: Enhancing Efficiency in Solar Panel Production

as a manufacturer of UV adhesives. Guangdong Huachuang Electronic Materials Co., Ltd. has been instrumental in enhancing efficiency in Solar Panel Production through the development of high-quality UV adhesives.

Solar panels have become increasingly poPUlar as a renewable energy source, and their production requires the use of reliable and efficient adhesives. These adhesives play a crucial role in bonding various components of a solar panel, such as solar cells, substrates, and encapsulation materials. Guangdong Huachuang Electronic Materials Co., Ltd. has been at the forefront of developing UV adhesives that meet the specific requirements of the solar panel industry.

One of the key challenges in solar panel production is achieving a strong and durable bond between different materials. The adhesive used must be able to withstand harsh environmental conditions, such as extreme temperatures, humidity, and UV radiation. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives that offer excellent adhesion strength and long-term durability, ensuring the reliability and performance of solar panels in various weather conditions.

Furthermore, the efficiency of solar panel production is greatly influenced by the curing time of the adhesive. Traditional adhesives often require long curing times, which can slow down the production process and result in increased costs. However, UV adhesives developed by Guangdong Huachuang Electronic Materials Co., Ltd. leverage the advancements in UV LED technology for faster and more efficient curing.

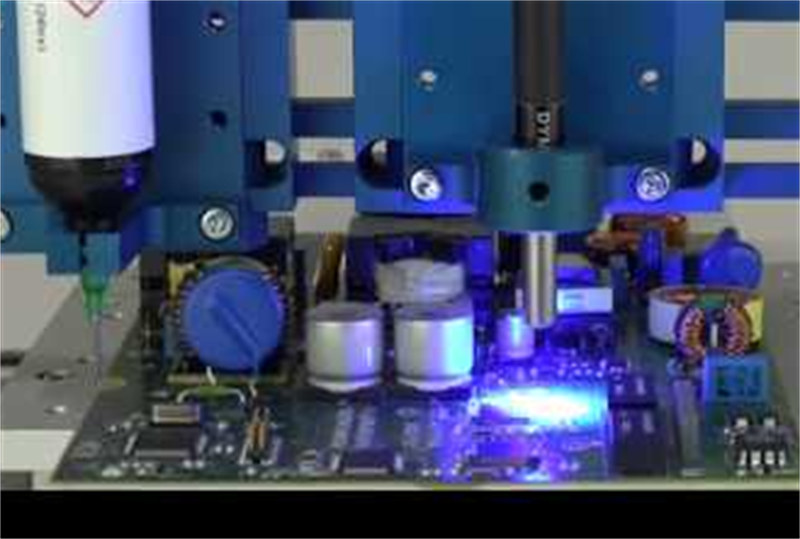

UV LED technology has revolutionized the curing process in adhesive applications. UV LED curing systems emit UV light of a specific wavelength, which triggers the curing reaction in UV adhesives. Compared to traditional curing methods, UV LED curing offers several advantages. It has a faster curing time, consumes less energy, and provides better control over the curing process.

The faster curing time of UV LED technology allows for increased production throughput. Manufacturers can achieve shorter cycle times and higher productivity, resulting in cost savings and improved efficiency. Guangdong Huachuang Electronic Materials Co., Ltd. understands the importance of optimizing production processes and has developed UV adhesives that cure quickly under UV LED light, enabling faster assembly and manufacturing of solar panels.

Additionally, UV LED curing systems consume less energy compared to traditional curing methods. This energy efficiency not only reduces operating costs but also contributes to a greener and more sustainable manufacturing process. Guangdong Huachuang Electronic Materials Co., Ltd. is committed to environmental sustainability and has incorporated UV LED technology into their UV adhesives to support eco-friendly solar panel production.

Moreover, UV LED curing systems provide better control over the curing process, resulting in consistent and reliable bond strength. Manufacturers can adjust the intensity and exposure time of the UV light to achieve the desired adhesive performance. Guangdong Huachuang Electronic Materials Co., Ltd. works closely with their customers to understand their specific requirements and develop UV adhesives that deliver optimal curing results for solar panel production.

Guangdong Huachuang Electronic Materials Co., Ltd. has invested in state-of-the-art manufacturing facilities and employs stringent quality control measures to ensure the performance and reliability of their UV adhesives. They conduct extensive research and development to continually improve their adhesive formulations and stay at the forefront of technological advancements in the industry.

In conclusion, Guangdong Huachuang Electronic Materials Co., Ltd. has played a crucial role in enhancing efficiency in solar panel production through their high-quality UV adhesives. By leveraging the advancements in UV LED technology, their adhesives offer fast curing times, energy efficiency, and precise control over the curing process. These qualities enable manufacturers to optimize their production processes, increase throughput, and achieve strong and durable bonds in solar panel assembly. Guangdong Huachuang Electronic Materials Co., Ltd. is a trusted partner for the solar panel industry, providing innovative adhesive solutions that contribute to the growth of renewable energy.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments