UV adhesive

UV Adhesives: Improving Bonding Performance in 3D Printing

Introduction:

As 3D printing continues to revolutionize manufacturing processes, the demand for advanced adhesive solutions to improve Bonding performance has become increasingly important. Guangdong Huachuang Electronic Materials Co., Ltd., a professional adhesive research and development and production enterprise based in Guangdong Province, China, has recognized this need and has been at the forefront of developing UV adhesives specifically tailored for 3D printing applications. With factories in Guangdong, Hunan, and Jiangsu provinces, the company has established itself as a leading manufacturer of UV adhesives, offering innovative solutions that enhance the bonding performance in 3D printing processes.

The Importance of Bonding Performance in 3D Printing:

In 3D printing, the quality of the bond between printed layers is crucial for the structural integrity and functionality of the final product. Traditional adhesives often struggle to provide strong and reliable bonds in 3D printed parts, leading to potential weaknesses and failures. This is where UV adhesives, developed by Guangdong Huachuang Electronic Materials Co., Ltd., come into play, offering significant improvements in bonding performance.

UV Adhesives for 3D Printing:

Guangdong Huachuang Electronic Materials Co., Ltd. has invested significant resources in researching and developing UV adhesives that are specifically designed for 3D printing applications. These adhesives are formulated to provide exceptional bonding strength, excellent adhesion to a wide range of 3D printing materials, and compatibility with various printing technologies.

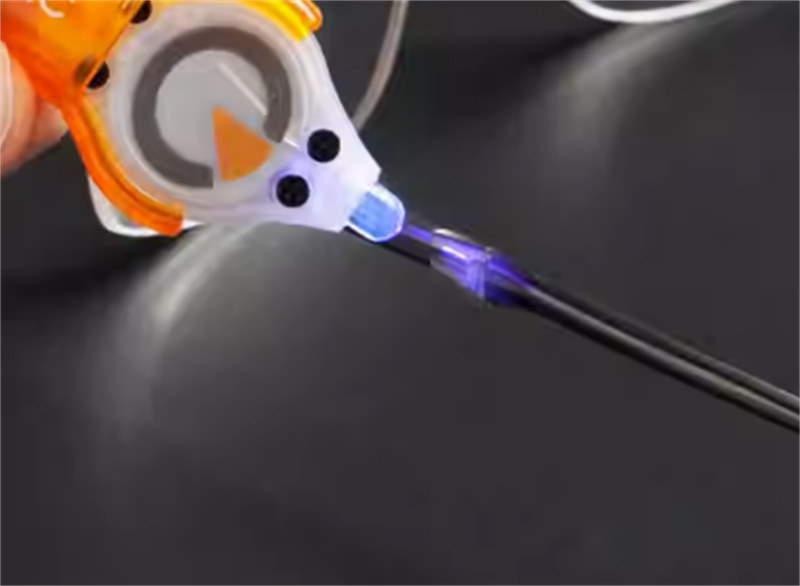

One of the key advantages of UV adhesives in 3D printing is their rapid curing time. Traditional adhesives often require long curing periods, which can significantly slow down the printing process. However, UV adhesives cure almost instantly when exposed to ultraviolet light, allowing for faster production times and increased efficiency. This quick curing process ensures that each printed layer bonds securely to the previous layer, resulting in a strong and durable final product.

Furthermore, UV adhesives offer excellent adhesion to a variety of 3D printing materials, including plastics, metals, ceramics, and composites. Guangdong Huachuang Electronic Materials Co., Ltd. has developed UV adhesives with optimized formulations that promote strong bonding on these materials, ensuring the structural integrity of the printed parts. This versatility allows 3D printing enthusiasts to work with a wide range of materials, expanding the possibilities for their creations.

In addition to their bonding strength and material compatibility, UV adhesives also offer other benefits that are particularly advantageous in 3D printing applications. These adhesives have low viscosity, allowing for easy application and uniform distribution across the printed layers. This ensures that the adhesive fills any gaps or imperfections, resulting in a smooth and seamless finish. Additionally, UV adhesives are often transparent, which is ideal for applications where aesthetics are important, such as in jewelry or architectural models.

Guangdong Huachuang Electronic Materials Co., Ltd. has also focused on developing UV adhesives that are resistant to environmental factors commonly encountered in 3D printing. These adhesives exhibit excellent resistance to temperature fluctuations, moisture, and chemicals, ensuring the durability of the bonded parts. This is particularly important for functional prototypes or end-use parts that may be exposed to challenging conditions.

Conclusion:

In the rapidly evolving world of 3D printing, the importance of reliable bonding performance cannot be overstated. Guangdong Huachuang Electronic Materials Co., Ltd. has recognized this need and has developed UV adhesives specifically tailored for 3D printing applications. These adhesives offer rapid curing times, excellent bonding strength, versatility in material compatibility, ease of application, and resistance to environmental factors.

As a leading manufacturer of UV adhesives, Guangdong Huachuang Electronic Materials Co., Ltd. continues to contribute to the advancement of 3D printing technology by providing innovative adhesive solutions. With their commitment to research and development, production excellence, and customer satisfaction, the company is poised to play a significant role in shaping the future of 3D printing.

In conclusion, the UV adhesives produced by Guangdong Huachuang Electronic Materials Co., Ltd. offer significant improvements in bonding performance for 3D printing applications. These adhesives provide rapid curing, exceptional bonding strength, compatibility with various 3D printing materials, ease of application, and resistance to environmental factors. With their dedication to innovation and quality, Guangdong Huachuang Electronic Materials Co., Ltd. is a trusted partner for 3D printing enthusiasts and manufacturers alike.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments