UV adhesive

Harnessing the Power of UV Curing: Applications of UV Adhesives

Guangdong Huachuang Electronic Materials Co., Ltd.: A Leader in UV Adhesives Research and Development

In the world of adhesives, UV adhesives have emerged as a game-changer. These adhesives offer fast curing times, excellent bonding strength, and versatility, making them a preferred choice in various industries. Guangdong Huachuang Electronic Materials Co., Ltd., a professional adhesive research and development enterprise based in Guangdong Province, China, has been at the forefront of UV adhesive innovation. With factories in Guangdong, Hunan, and Jiangsu Provinces, the company has been providing high-quality UV adhesives since its establishment in 1999.

Understanding UV Adhesives:

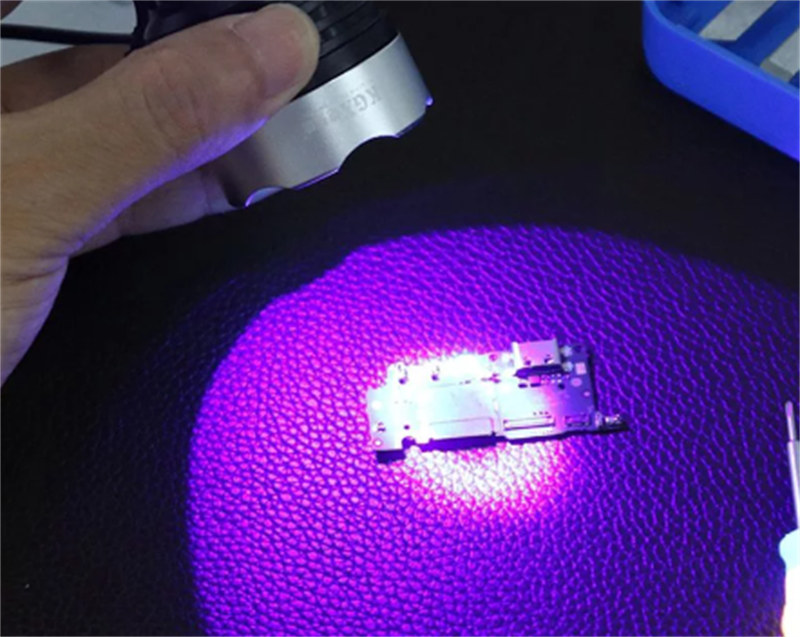

UV adhesives, also known as UV-curable adhesives, are a type of adhesive that cures rapidly when exposed to ultraviolet (UV) light. These adhesives are typically composed of a mixture of monomers, oligomers, photoinitiators, and various additives. When the adhesive is exposed to UV light, the photoinitiators initiate a chemical reaction that causes the adhesive to harden or cure.

Advantages of UV Adhesives:

1. Fast Curing: One of the significant advantages of UV adhesives is their fast curing time. Unlike traditional adhesives that require hours or even days to fully cure, UV adhesives can cure within seconds or minutes when exposed to UV light. This rapid curing time significantly improves production efficiency and reduces assembly time.

2. High Bonding Strength: UV adhesives offer excellent bonding strength, making them suitable for a wide range of applications. Whether it is bonding glass, metal, plastic, or other materials, UV adhesives form strong and durable bonds. This high bonding strength ensures the integrity of the bonded components, even in demanding environments.

3. Versatility: UV adhesives are highly versatile and can be used in various industries and applications. From electronics and automotive to medical devices and aerospace, UV adhesives find their applications in diverse sectors. They can be used for bonding, sealing, encapsulating, coating, and even 3D printing.

4. Environmental Friendliness: UV adhesives are considered environmentally friendly due to their low volatile organic compound (VOC) content. Unlike solvent-based adhesives, UV adhesives do not release harmful VOCs during curing, making them safer for both the environment and the workers handling them.

Applications of UV Adhesives:

1. Electronics: UV adhesives are widely used in the electronics industry for bonding components, encapsulating sensitive electronics, and sealing displays. Their fast curing time and high bond strength make them ideal for high-volume production processes.

2. Automotive: In the automotive industry, UV adhesives are used for bonding and sealing applications. They are used in the assembly of headlights, taillights, interior components, and even in glass bonding. The high bond strength and resistance to temperature and vibrations make UV adhesives suitable for automotive applications.

3. Medical Devices: UV adhesives find extensive use in the medical device industry due to their biocompatibility and sterilization resistance. They are used for bonding medical device components, sealing medical packaging, and even in dental applications.

4. Optics: The optical industry relies on UV adhesives for bonding and sealing optical components, such as lenses, prisms, and filters. The high transparency and low shrinkage properties of UV adhesives make them ideal for optical applications.

Guangdong Huachuang Electronic Materials Co., Ltd.: A Leader in UV Adhesives

Guangdong Huachuang Electronic Materials Co., Ltd. has been a leading manufacturer of UV adhesives for over two decades. With their expertise in adhesive technology and commitment to research and development, the company has developed a wide range of UV adhesives that cater to various industries and applications.

The company's UV adhesives are known for their high quality, excellent bonding strength, and fast curing times. They offer a comprehensive range of UV adhesives suitable for different substrates, including glass, metal, plastic, and ceramics. The adhesives are designed to provide optimal performance in terms of bond strength, flexibility, and resistance to temperature, chemicals, and environmental factors.

Guangdong Huachuang Electronic Materials Co., Ltd. also provides customized solutions to meet specific customer requirements. Their team of experts works closely with customers to understand their needs and develop tailor-made UV adhesive formulations. This commitment to customer satisfaction has earned them a rePUtation as a trusted partner in the adhesive industry.

Research and Development:

Guangdong Huachuang Electronic Materials Co., Ltd. places great emphasis on research and development to stay at the forefront of UV adhesive innovation. The company has a dedicated team of scientists and engineers who work tirelessly to develop new adhesive formulations and improve existing ones.

The company invests heavily in advanced equipment and technology to facilitate their research and development efforts. They have state-of-the-art laboratories equipped with cutting-edge testing and analysis equipment. This allows them to conduct rigorous testing and quality control measures to ensure the performance and reliability of their UV adhesives.

Guangdong Huachuang Electronic Materials Co., Ltd. also collaborates with universities, research institutions, and industry experts to stay updated with the latest advancements in adhesive technology. This collaborative approach helps them gain valuable insights and incorporate new ideas into their adhesive formulations.

Production and Quality Control:

Guangdong Huachuang Electronic Materials Co., Ltd. has established modern production facilities in Guangdong, Hunan, and Jiangsu Provinces to meet the growing demand for UV adhesives. These facilities are equipped with advanced production lines and adhere to strict quality control measures to ensure the consistency and reliability of their products.

The company follows international quality management standards and has obtained certifications such as ISO9001 and ISO14001. These certifications reflect their commitment to delivering high-quality products that meet or exceed customer expectations.

Guangdong Huachuang Electronic Materials Co., Ltd. also places great importance on sustainability and environmental responsibility. They have implemented measures to minimize waste, reduce energy consumption, and optimize production processes to minimize their environmental impact.

Conclusion:

UV adhesives have revolutionized the adhesive industry with their fast curing times, high bonding strength, and versatility. They find applications in various industries, including electronics, automotive, medical devices, and optics. Guangdong Huachuang Electronic Materials Co., Ltd. has been a key player in the UV adhesive market, providing high-quality adhesive solutions to meet the demands of different industries. With their focus on research and development, the company continues to innovate and develop new UV adhesive formulations to address the evolving needs of the market. Their commitment to quality, customer satisfaction, and environmental responsibility has made them a trusted partner in the adhesive industry.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments