UV adhesive

What is UV curable 3D printing?

UV curable 3D printing, also known as stereolithography or digital light processing (DLP), is a process of creating three-dimensional objects by using a UV curable resin that solidifies when exposed to UV light. It is a poPUlar method in additive manufacturing for its high precision, speed, and ability to produce complex geometries.

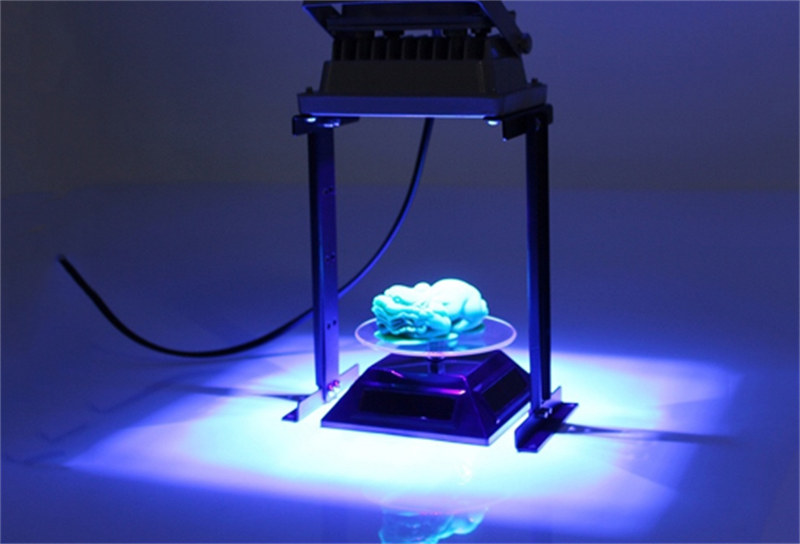

In UV curable 3D printing, a UV curable resin is used as the printing material. This resin is typically composed of a mixture of liquid monomers, oligomers, photoinitiators, and other additives. The resin is poured into a vat or reservoir, and a build platform is submerged in the resin. A UV light source, such as a laser or a projector, then selectively exposes the resin to UV light, solidifying it layer by layer.

The process starts by creating a digital model of the desired object using computer-aided design (CAD) software. The software then slices the digital model into thin layers, which are used as a guide for the printing process. The UV light source scans or projects the pattern of each layer onto the resin, causing it to solidify and adhere to the previous layer. This process is repeated layer by layer until the entire object is created.

UV curable 3D printing offers several advantages over other 3D printing technologies. One of the key advantages is its high precision and resolution. The ability to selectively expose the resin to UV light allows for the creation of intricate details and fine features. This makes UV curable 3D printing suitable for applications that require high accuracy and intricate designs, such as jewelry, dental models, and prototyping.

Another advantage of UV curable 3D printing is its fast printing speed. The UV curable resin solidifies quickly when exposed to UV light, allowing for rapid layer-by-layer printing. Compared to other 3D printing methods, UV curable 3D printing can produce objects in a shorter amount of time, improving overall efficiency and productivity.

UV curable 3D printing also enables the production of objects with a smooth surface finish. The UV curable resin has low viscosity, which allows it to flow and fill in fine details and complex geometries. This results in objects with a high level of surface detail and smoothness. Additionally, the cured resin has excellent dimensional stability, ensuring that the printed object retains its shape and size.

Guangdong Huachuang Electronic Materials Co., Ltd. is a professional adhesive and new material research and development and production enterprise based in Guangdong Province, China. With their expertise in adhesive technology, the company offers UV curable resins specifically designed for 3D printing applications. Their UV curable resins are known for their high quality, compatibility with different 3D printers, and excellent printing performance.

In conclusion, UV curable 3D printing is a versatile and efficient additive manufacturing process that utilizes a UV curable resin to create three-dimensional objects. It offers high precision, fast printing speed, and the ability to produce objects with smooth surface finishes. Guangdong Huachuang Electronic Materials Co., Ltd. is a leading manufacturer of UV curable resins for 3D printing, providing high-quality materials for various applications.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments