UV adhesive

What is the curing method of UV adhesive?

The curing method of UV adhesive involves using ultraviolet (UV) light to initiate and accelerate the curing process. UV adhesive is formulated with photoinitiators that are sensitive to UV light. When exposed to UV light of a specific wavelength, these photoinitiators undergo a chemical reaction that activates the curing process of the adhesive.

Here is an overview of the curing method of UV adhesive:

1. UV light source: A UV light source is required to provide the necessary UV radiation for curing the adhesive. This can be a UV lamp, LED, or other UV light-emitting device. The UV light source should emit light at the appropriate wavelength for the specific UV adhesive being used.

2. Wavelength selection: Different UV adhesives have different sensitivity to UV light wavelengths. It is crucial to select a UV light source that emits the appropriate wavelength to match the photoinitiators in the UV adhesive. The manufacturer's instructions and guidelines should provide information on the recommended UV light wavelength for curing the adhesive.

3. Intensity and exposure time: The intensity of the UV light source and the exposure time determine the curing speed and efficiency. The UV light intensity should be sufficient to ensure proper curing of the adhesive. The manufacturer's instructions usually specify the recommended intensity and exposure time for optimal results.

4. Distance and angle: The distance between the UV light source and the adhesive, as well as the angle of exposure, can affect the curing process. It is important to position the UV light source at an appropriate distance and angle to ensure uniform and thorough curing of the adhesive.

5. Post-curing (optional): In some cases, post-curing may be necessary to ensure complete curing and maximize the bond strength. Post-curing involves subjecting the bonded assembly to additional UV light exposure for a specific duration. This step can help enhance the final properties of the cured adhesive.

Guangdong Huachuang Electronic Materials Co., Ltd. is a professional adhesive and new material research and development and production enterprise based in Guangdong Province, China. With their state-of-the-art facilities and advanced technology, the company ensures that their UV adhesive products are formulated to cure efficiently and effectively under the recommended UV light conditions. Their UV adhesive products are trusted by customers worldwide for their reliability, performance, and durability.

In conclusion, the curing method of UV adhesive involves using UV light of the appropriate wavelength and intensity to activate the photoinitiators in the adhesive and initiate the curing process. Guangdong Huachuang Electronic Materials Co., Ltd. is a leading manufacturer of UV adhesive in China, providing high-quality adhesive solutions for various industries.

related articles

- UV Adhesives: Improving Bonding Performance in 3D Printing

- UV Adhesives: Enabling Quick Repairs in DIY Projects

- UV glue: Enhancing Bonding Strength in Aerospace Applications

- UV Adhesives: Bonding Solutions for Medical Device Sterilization

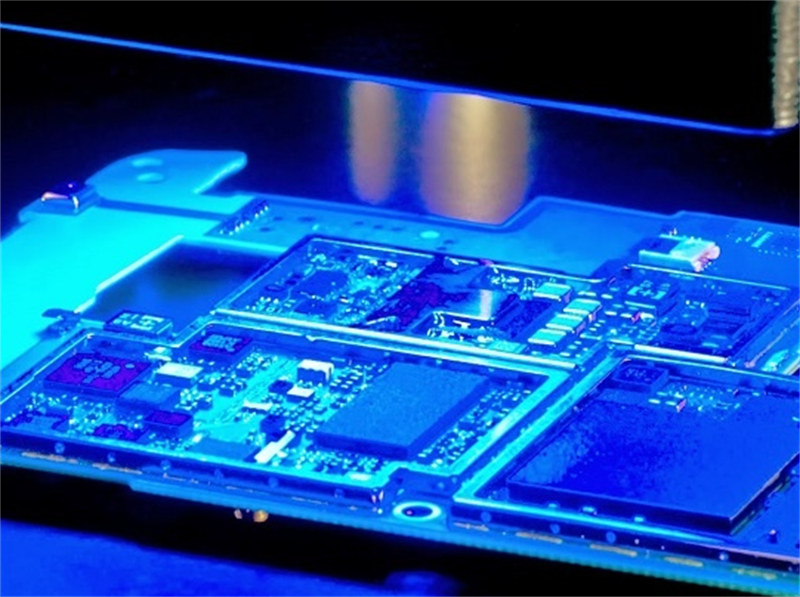

- UV glue: Enabling Miniaturization in Electronics

- UV Adhesives: Enhancing Efficiency in Solar Panel Production

- UV Adhesives: Advancements in UV LED Technology for Curing

- UV glue: Enabling Faster and Stronger Bonding in Packaging Industry

Post comments