Epoxy adhesive

Understanding the Chemical Properties of Epoxy Resin Potting Materials

Understanding the Chemical Properties of Epoxy Resin Potting Materials

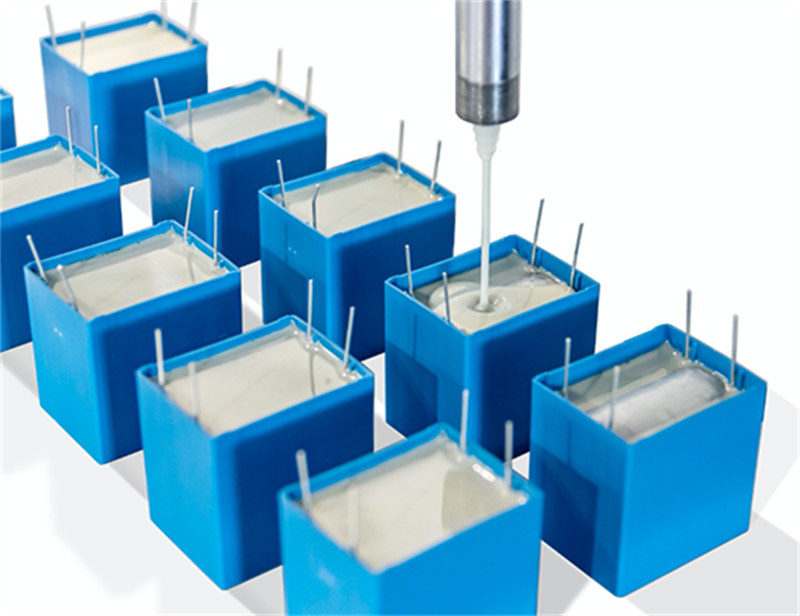

Epoxy Resin potting materials are widely used in the electronics industry to protect and encapsulate sensitive electronic components. These materials offer excellent protection against environmental factors, mechanical stability, thermal management, and electrical insulation. In this article, we will delve deeper into the chemical properties of Epoxy Resin Potting materials and how they contribute to the overall performance and reliability of electronic devices.

Chemical Composition of Epoxy Resin Potting Materials

Epoxy resin potting materials are typically composed of a mixture of Epoxy resin, hardeners, and various additives. The epoxy resin acts as the main binder, providing the material with its adhesive properties and mechanical strength. The hardeners, often referred to as curing agents, are added to initiate the cross-linking reaction between the epoxy resin molecules, leading to the formation of a solid, durable material.

Additives are incorporated into the epoxy resin potting materials to enhance specific properties or provide additional functionalities. These additives can include fillers, flame retardants, antioxidants, UV stabilizers, and colorants. Fillers, such as silica or alumina, are commonly added to improve the mechanical strength and thermal conductivity of the material. Flame retardants are included to reduce the flammability of the potting material, making it safer for use in electronic devices.

Chemical Reactions and Curing Process

The curing process of epoxy resin potting materials involves a chemical reaction between the epoxy resin and the hardeners. This reaction is known as cross-linking and results in the formation of a three-dimensional network of interconnected polymer chains. The cross-linking process can be initiated by various mechanisms, including heat, UV light, or the addition of a catalyst.

During the curing process, the epoxy resin molecules react with the hardeners, forming covalent bonds between them. This cross-linking reaction leads to the transformation of the liquid mixture into a solid material with enhanced mechanical and thermal properties. The curing time and temperature can be adjusted to control the rate of the reaction and achieve the desired material properties.

Chemical Resistance and Environmental Protection

Epoxy resin potting materials offer excellent chemical resistance, protecting electronic components from exposure to moisture, chemicals, and corrosive substances. The cured epoxy resin forms a barrier that prevents these substances from reaching the sensitive components, reducing the risk of damage or degradation.

The chemical resistance of epoxy resin potting materials can be further enhanced by the addition of specific additives. For example, the incorporation of UV stabilizers can protect the material from degradation caused by prolonged exposure to sunlight. Flame retardants can improve the material's resistance to flammable chemicals, reducing the risk of fire in electronic devices.

Mechanical Stability and Thermal Management

Epoxy resin potting materials provide exceptional mechanical stability, ensuring that electronic components remain securely in place and protected from mechanical stress. The cured material acts as a rigid encapsulation, preventing the components from shifting or becoming damaged due to vibrations, shocks, or impacts.

Thermal management is another critical aspect of epoxy resin potting materials. Electronic components generate heat during operation, and excessive heat can negatively impact their performance and lifespan. Epoxy resin potting materials with high thermal conductivity can effectively dissipate heat, keeping the components within safe temperature ranges. This thermal management capability is particularly important for devices that generate significant heat, such as power electronics or LED lighting systems.

Electrical Insulation

Epoxy resin potting materials provide excellent electrical insulation properties, preventing electrical short circuits and leakage currents. The cured material acts as an insulating barrier, preventing the flow of electrical current between conductive elements. This insulation is crucial for devices that operate at high voltages or in proximity to conductive materials, ensuring the safe and reliable operation of the electronic components.

Professional Adhesive/New Material R&D and Production Enterprises

To ensure the reliability and performance of epoxy resin potting materials, it is essential to work with professional adhesive/new material R&D and production enterprises. These enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., founded in 1999, specialize in the research, development, and production of high-quality epoxy resin potting materials.

Guangdong Huachuang Electronic Materials Co., Ltd. is a leading provider of epoxy resin potting materials, offering a wide range of products tailored to meet the specific requirements of different industries and applications. With their expertise in adhesive and new material development, they continuously innovate to improve the properties and performance of their epoxy resin potting materials.

Quality control is a top priority for professional adhesive/new material R&D and production enterprises. They follow stringent quality control processes to ensure the reliability and consistency of their epoxy resin potting materials. Comprehensive testing and analysis are conducted to verify the performance characteristics, including bonding strength, thermal management capabilities, and chemical resistance.

Furthermore, professional enterprises like Guangdong Huachuang Electronic Materials Co., Ltd. offer customization options to tailor epoxy resin potting materials to specific customer needs. They work closely with customers to understand their requirements and provide technical support throughout the selection and implementation process. This collaboration ensures that the chosen epoxy resin potting materials enhance the performance and reliability of electronic devices.

Conclusion

Epoxy resin potting materials are essential for protecting and encapsulating electronic components, providing environmental protection, mechanical stability, thermal management, and electrical insulation. The chemical composition, curing process, and additives used in epoxy resin potting materials contribute to their overall performance and reliability.

Working with professional adhesive/new material R&D and production enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., ensures the availability of high-quality epoxy resin potting materials that meet industry standards and customer expectations. These enterprises offer expertise in research and development, stringent quality control processes, and customization options to provide cost-effective solutions for electronic encapsulation. With their support, manufacturers can enhance the performance and reliability of their electronic devices, ensuring their longevity and functionality in various applications.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments