Epoxy adhesive

Epoxy Resin Potting Compounds: A Cost-Effective Solution for Electronic Encapsulation

Epoxy Resin Potting Compounds: A Cost-Effective Solution for Electronic Encapsulation

Introduction:

In today's technologically advanced world, electronic devices are an integral part of our daily lives. From smartphones and laptops to automotive systems and industrial machinery, electronic components are present in almost every aspect of our lives. However, these components are often exposed to harsh environments that can negatively impact their performance and lifespan. To ensure the reliability and longevity of electronic devices, manufacturers rely on effective protective measures such as Epoxy Resin Potting compounds. In this article, we will explore the benefits of Epoxy Resin potting compounds and how professional adhesive/new material R&D and production enterprises, like Guangdong Huachuang Electronic Materials Co., Ltd., can provide cost-effective solutions for electronic encapsulation.

Understanding Epoxy Resin Potting Compounds:

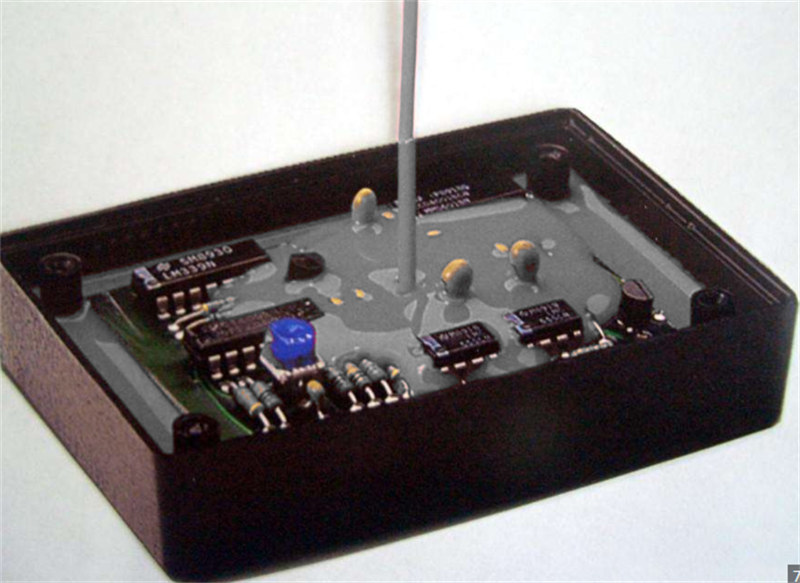

Epoxy resin potting compounds are specialized adhesives that are used to encapsulate electronic components and create a protective barrier around them. These compounds are made from a mixture of epoxy resin, hardeners, and various additives, which provide the desired properties such as environmental protection, mechanical stability, and thermal management.

Benefits of Epoxy Resin Potting Compounds:

1. Environmental Protection: One of the primary benefits of epoxy resin potting compounds is their ability to protect electronic components from harsh environmental factors. These compounds are highly resistant to moisture, dust, and chemicals, preventing them from reaching the sensitive components and causing damage. This environmental protection is crucial for electronic devices used in outdoor or industrial settings, where exposure to moisture, dust, or corrosive substances is common.

2. Mechanical Stability: Epoxy resin potting compounds provide excellent mechanical stability to electronic devices. They act as a protective barrier, securing delicate components in place and preventing them from shifting or becoming damaged due to mechanical stress. This is particularly important in applications where the devices may experience vibrations, shocks, or impacts, such as automotive electronics or machinery control systems.

3. Thermal Management: Electronic components generate heat during operation, and excessive heat can degrade their performance and lifespan. Epoxy resin potting compounds with high thermal conductivity can effectively dissipate heat, ensuring that the components operate within safe temperature ranges. This thermal management capability is critical for devices that generate significant heat, such as power electronics or LED lighting systems.

4. Electrical Insulation: Epoxy resin potting compounds provide excellent electrical insulation properties, preventing electrical short circuits and leakage currents. This insulation is vital for devices that operate at high voltages or in proximity to conductive materials. By insulating the components, epoxy resin potting compounds ensure the safe and reliable operation of the devices.

Professional Adhesive/New Material R&D and Production Enterprises:

Professional adhesive/new material R&D and production enterprises play a crucial role in the development and supply of high-quality epoxy resin potting compounds. These enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., founded in 1999, specialize in the research, development, and production of advanced adhesive materials. They offer cost-effective solutions for electronic encapsulation by providing the following:

1. Research and Development Expertise: Professional enterprises have dedicated teams of experts who possess extensive knowledge and experience in adhesive and new material development. They continually research and innovate to create epoxy resin potting compounds with enhanced properties, such as improved bonding strength, thermal conductivity, and chemical resistance. This expertise ensures that the compounds meet the specific requirements of different industries and applications.

2. Quality Control: Professional enterprises follow stringent quality control processes to ensure the reliability and consistency of their epoxy resin potting compounds. They conduct comprehensive testing and analysis to verify the performance characteristics, including bonding strength and thermal management capabilities. This quality control ensures that the compounds meet industry standards and customer expectations, providing cost-effective solutions for electronic encapsulation.

3. Customization and Technical Support: Professional enterprises understand that different electronic devices have unique requirements. They offer customization options to tailor epoxy resin potting compounds to specific customer needs. By collaborating closely with customers, these enterprises provide technical support throughout the selection and implementation process, ensuring that the chosen compounds enhance performance and reliability in the targeted applications.

Guangdong Huachuang Electronic Materials Co., Ltd.:

Guangdong Huachuang Electronic Materials Co., Ltd. is a professional adhesive/new material R&D and production enterprise founded in 1999. The company specializes in the research, development, and production of high-quality epoxy resin potting compounds. With a focus on innovation and customer satisfaction, Guangdong Huachuang Electronic Materials Co., Ltd. offers cost-effective solutions for electronic encapsulation. Their commitment to quality and technical expertise makes them a reliable partner for manufacturers seeking to enhance performance and reliability in their electronic devices.

Conclusion:

Epoxy resin potting compounds are a cost-effective solution for electronic encapsulation, providing environmental protection, mechanical stability, thermal management, and electrical insulation. Professional adhesive/new material R&D and production enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., play a vital role in this process. Through their research and development expertise, quality control processes, and customization options, these enterprises provide high-quality epoxy resin potting compounds that meet the specific requirements of different industries. With their support, manufacturers can achieve superior performance and reliability in their electronic devices.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments