Epoxy adhesive

Overcoming Challenges with Epoxy Resin Potting: Tips and Techniques

Overcoming Challenges with Epoxy Resin Potting: Tips and Techniques

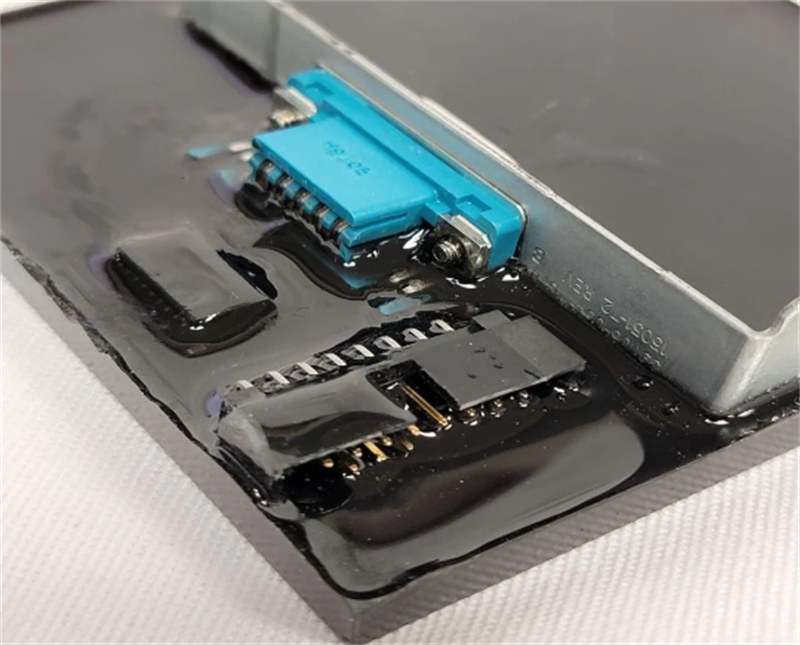

Epoxy Resin potting is a widely used technique for encapsulating and protecting electronic components. However, like any manufacturing process, it comes with its own set of challenges. From ensuring proper adhesion to achieving optimal curing, there are several factors to consider when working with Epoxy Resin Potting materials. In this article, we will discuss some tips and techniques for overcoming these challenges and achieving successful Epoxy resin potting.

1. Surface Preparation: One of the key factors in achieving good adhesion between the epoxy resin and the substrate is proper surface preparation. Before applying the epoxy resin, it is crucial to clean the surface thoroughly to remove any dirt, dust, or contaminants. This can be done using solvents, such as isopropyl alcohol, and a lint-free cloth. Additionally, roughening the surface with sandpaper or a wire brush can improve adhesion by creating a mechanical bond.

2. Mixing Ratios: Epoxy resin potting materials typically consist of two components - the epoxy resin and the hardener. It is essential to follow the recommended mixing ratios provided by the manufacturer. Deviating from the specified ratios can result in incomplete curing or weak adhesion. Use accurate measuring tools, such as a digital scale or graduated cylinders, to ensure precise measurements.

3. Degassing: Air bubbles trapped within the epoxy resin can compromise the quality and performance of the potting material. To remove these bubbles, it is important to degas the mixture before pouring it into the mold or onto the substrate. This can be done using a vacuum chamber or a degassing pot. Applying a vacuum to the mixture helps to release trapped air, resulting in a bubble-free potting material.

4. Curing Time and Temperature: The curing time and temperature play a crucial role in achieving optimal properties in epoxy resin potting materials. It is important to follow the manufacturer's recommendations regarding the curing conditions. Curing at too low a temperature or for too short a time can result in incomplete curing, leading to weak mechanical properties. On the other hand, curing at too high a temperature or for too long can cause thermal degradation of the potting material.

5. Post-Curing: After the initial curing process, some epoxy resin potting materials may benefit from a post-curing step. Post-curing involves subjecting the cured material to elevated temperatures for an extended period. This helps to further enhance the mechanical and thermal properties of the potting material. However, not all epoxy resin potting materials require post-curing, so it is important to consult the manufacturer's guidelines.

6. Compatibility with Components: Epoxy resin potting materials come in a variety of formulations, each with its own set of properties. It is important to select a potting material that is compatible with the specific electronic components being encapsulated. Factors such as thermal conductivity, coefficient of thermal expansion, and chemical resistance should be considered to ensure that the potting material does not adversely affect the performance of the components.

7. Testing and Validation: Before implementing epoxy resin potting on a large scale, it is crucial to conduct thorough testing and validation. This involves testing the potting material for its mechanical, thermal, and electrical properties. Additionally, compatibility testing with the specific components and environmental conditions should be performed to ensure long-term reliability. Working with a professional adhesive/new material R&D and production enterprise can provide access to comprehensive testing facilities and expertise.

Guangdong Huachuang Electronic Materials Co., Ltd.: A Trusted Partner

When it comes to epoxy resin potting materials, partnering with a professional adhesive/new material R&D and production enterprise is crucial. Guangdong Huachuang Electronic Materials Co., Ltd. is a leading provider of epoxy resin potting materials, specializing in the research, development, and production of high-quality solutions.

With over 20 years of experience, Guangdong Huachuang Electronic Materials Co., Ltd. has established itself as a trusted partner for manufacturers seeking reliable and high-performance epoxy resin potting materials. Their expertise in adhesive and new material development allows them to offer a wide range of products tailored to meet the specific requirements of different industries and applications.

Guangdong Huachuang Electronic Materials Co., Ltd. follows stringent quality control processes to ensure the reliability and consistency of their epoxy resin potting materials. They conduct comprehensive testing and analysis to verify the performance characteristics, including bonding strength, thermal management capabilities, and chemical resistance. This commitment to quality ensures that their potting materials meet industry standards and customer expectations.

In addition to their extensive product range, Guangdong Huachuang Electronic Materials Co., Ltd. offers customization options to tailor epoxy resin potting materials to specific customer needs. They work closely with customers to understand their requirements and provide technical support throughout the selection and implementation process. This collaboration ensures that the chosen epoxy resin potting materials enhance the performance and reliability of electronic devices.

Conclusion

Epoxy resin potting is a widely used technique for encapsulating and protecting electronic components. By following the tips and techniques discussed in this article, manufacturers can overcome the challenges associated with epoxy resin potting and achieve successful encapsulation. Partnering with a professional adhesive/new material R&D and production enterprise like Guangdong Huachuang Electronic Materials Co., Ltd. ensures access to high-quality epoxy resin potting materials that meet industry standards and customer expectations. With their support, manufacturers can enhance the performance and reliability of their electronic devices, ensuring their longevity and functionality in various applications.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments