Epoxy adhesive

Epoxy Resin Potting: Mitigating the Effects of Vibration on Electronic Assemblies

Epoxy Resin Potting: Mitigating the Effects of Vibration on Electronic Assemblies

Vibration is a common challenge that electronic assemblies face in various applications, including automotive, aerospace, and industrial environments. These vibrations can cause significant damage to electronic components, leading to malfunctions, decreased performance, and even complete failure. To mitigate the effects of vibration and ensure the reliability and longevity of electronic assemblies, Epoxy Resin Potting has emerged as an effective solution.

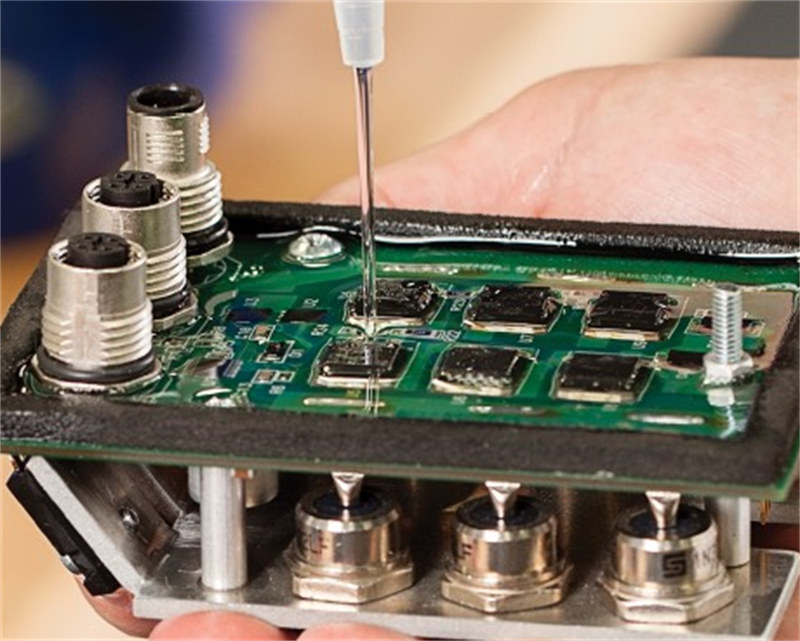

Epoxy Resin potting involves encapsulating electronic components or circuits in a resin material, typically Epoxy-based, to create a protective barrier. This encapsulation process not only protects the components from external elements but also provides insulation, mechanical support, and environmental protection.

One of the primary benefits of epoxy resin potting is its ability to dampen vibrations. The resin material absorbs and dissipates the energy generated by vibrations, reducing the impact on the electronic components. This damping effect helps prevent damage caused by excessive movement or stress, ensuring the stability and reliability of the assembly.

Epoxy resin potting materials also offer excellent adhesion properties, which further enhance their effectiveness in mitigating the effects of vibration. The resin forms a strong bond with the components and the substrate, providing mechanical stability and preventing the components from shifting or vibrating. This reduces the risk of damage or failure due to mechanical stress induced by vibrations.

In addition to damping vibrations, epoxy resin potting materials can also provide shock resistance. In applications where electronic assemblies are subjected to sudden impacts or shocks, the resin material acts as a cushion, absorbing and dispersing the energy to protect the components. This shock resistance capability ensures the longevity and reliability of the assemblies, even in rugged environments.

To ensure the highest quality and reliability of epoxy resin potting materials, it is crucial to partner with a professional adhesive and new material R&D and production enterprise. Guangdong Huachuang Electronic Materials Co., Ltd., located in Guangdong Province, China, is a leading company in this field. Founded in 1999, the company has extensive experience and expertise in developing and producing epoxy resin potting materials.

Guangdong Huachuang Electronic Materials Co., Ltd. is dedicated to research and development, continuously improving and innovating their epoxy resin potting solutions. They utilize advanced manufacturing processes and rigorous quality control measures to deliver products that meet the highest industry standards. Their epoxy resin potting materials are tailored to the specific requirements of different applications, ensuring optimal protection against vibration-induced damage.

In conclusion, epoxy resin potting is an effective method for mitigating the effects of vibration on electronic assemblies. By dampening vibrations, providing excellent adhesion, and offering shock resistance, epoxy resin potting materials ensure the stability, reliability, and longevity of electronic assemblies. When seeking epoxy resin potting solutions, partnering with a professional adhesive and new material R&D and production enterprise like Guangdong Huachuang Electronic Materials Co., Ltd. ensures the highest quality and reliability of the potting materials. With their expertise and commitment to innovation, they can provide tailored solutions that protect electronic assemblies from vibration-induced damage, enabling their optimal performance and longevity.

related articles

- The Role of Epoxy Resin AB Adhesive in the Defense and Security Sector

- Epoxy Resin AB Adhesive: A Cost-Effective Solution for Industrial Maintenance

- Exploring the Fire-Resistant Properties of Epoxy Resin AB Adhesive

- Epoxy Resin AB Adhesive: Ensuring Safety and Reliability in Transportation Systems

- The Role of Epoxy Resin AB Adhesive in Medical Device Manufacturing

- Epoxy Resin AB Adhesive: A Reliable Choice for Electrical and Electronic Applications

- How Epoxy Resin AB Adhesive Enhances Structural Integrity in Civil Engineering

- Epoxy Resin AB Adhesive: Overcoming Challenges in High-Temperature Environments

Post comments