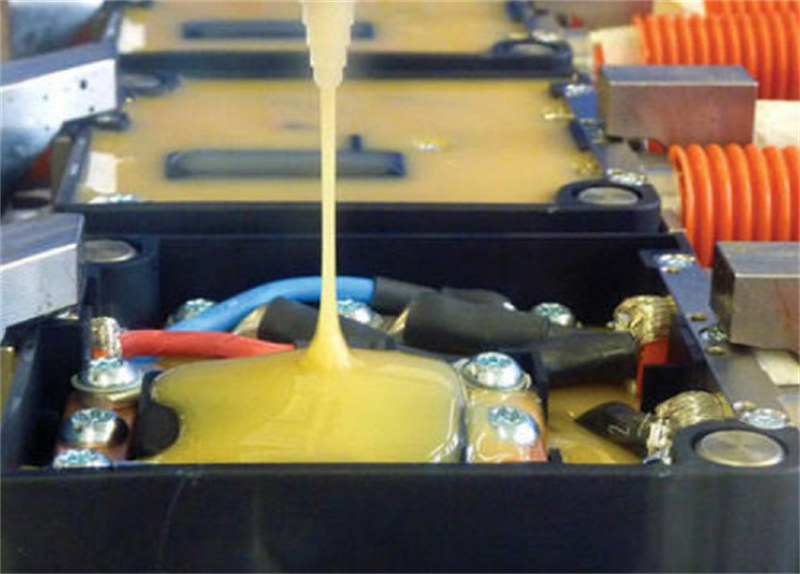

Epoxy adhesive

The Future of Epoxy Resin Potting: Advancements and Innovations

The Future of Epoxy Resin Potting: Advancements and Innovations

Epoxy resin potting compounds have been a staple in the electronics manufacturing industry for their ability to provide excellent protection and insulation for electronic components. As technology continues to advance, the demand for more advanced and innovative Epoxy Resin Potting solutions is on the rise. Professional adhesive/new material R&D and production enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., founded in 1999, play a crucial role in driving Advancements and innovations in Epoxy Resin potting.

Advancements in Formulation

One of the key areas of advancement in epoxy resin potting is the formulation of the compounds. Professional adhesive enterprises like Guangdong Huachuang Electronic Materials Co., Ltd. invest in research and development to continuously improve the formulation of their epoxy resin potting compounds. This involves developing new resin systems and additives that offer enhanced performance and properties.

For example, there is a growing demand for epoxy resin potting compounds that can withstand higher operating temperatures. With the increasing use of power electronics and LED lighting, electronic components are exposed to higher temperatures, requiring potting compounds that can withstand these conditions without compromising performance. Professional adhesive enterprises are investing in the development of high-temperature epoxy resin potting compounds that offer excellent thermal stability and insulation properties.

In addition to temperature resistance, advancements are also being made in developing epoxy resin potting compounds with improved electrical properties. As electronic devices become more complex and miniaturized, the need for potting compounds with high dielectric strength and low dielectric constant is increasing. Professional adhesive enterprises are working on developing epoxy resin formulations that offer superior electrical insulation properties, allowing for better performance and reliability of electronic components.

Innovative Application Techniques

Alongside advancements in formulation, innovative application techniques are also driving the future of epoxy resin potting. Traditional potting methods involve pouring or injecting the epoxy resin compound into the electronic device or component. However, as the complexity of electronic devices increases, there is a need for more precise and efficient potting techniques.

One such innovative technique is vacuum potting, which involves placing the electronic device or component in a vacuum chamber and then filling it with epoxy resin. The vacuum helps to remove any trapped air bubbles, ensuring a more uniform and reliable potting. This technique is particularly useful for potting sensitive electronic components that are prone to damage from air bubbles or voids.

Another innovative application technique is dispensing robots, which automate the potting process. These robots can precisely dispense the epoxy resin potting compound in a controlled manner, ensuring consistent coverage and avoiding any potential human errors. This automation not only improves the efficiency of the potting process but also reduces the risk of contamination or uneven potting.

Professional adhesive enterprises like Guangdong Huachuang Electronic Materials Co., Ltd. are at the forefront of these innovative application techniques. They invest in advanced equipment and technology to provide manufacturers with state-of-the-art potting solutions that improve productivity, accuracy, and reliability.

Environmentally Friendly Solutions

As environmental concerns continue to grow, there is a rising demand for epoxy resin potting compounds that are more environmentally friendly. Professional adhesive enterprises are actively working on developing sustainable and eco-friendly solutions to meet these demands.

One area of focus is the development of epoxy resin potting compounds that are free from harmful substances, such as heavy metals or volatile organic compounds (VOCs). By adhering to international safety regulations, such as RoHS and REACH, professional adhesive enterprises ensure that their epoxy resin potting compounds are safe for both users and the environment.

Additionally, there is a push towards developing epoxy resin potting compounds that are biodegradable or recyclable. This allows for easier disposal and reduces the environmental impact of electronic waste. Professional adhesive enterprises are exploring alternative materials and additives that can enhance the biodegradability or recyclability of epoxy resin potting compounds without compromising their performance or properties.

Conclusion

The future of epoxy resin potting is filled with advancements and innovations that aim to meet the evolving needs of the electronics manufacturing industry. Professional adhesive/new material R&D and production enterprises, such as Guangdong Huachuang Electronic Materials Co., Ltd., founded in 1999, are at the forefront of driving these advancements.

Through continuous research and development, professional adhesive enterprises are improving the formulation of epoxy resin potting compounds to offer enhanced performance, such as higher temperature resistance and improved electrical properties. They are also exploring innovative application techniques, such as vacuum potting and dispensing robots, to improve the efficiency and reliability of the potting process.

Furthermore, professional adhesive enterprises are actively working on developing environmentally friendly solutions, including epoxy resin potting compounds that are free from harmful substances and those that are biodegradable or recyclable. By prioritizing sustainability, they are contributing to minimizing the environmental impact of electronic waste.

As technology continues to advance, the demand for more advanced epoxy resin potting solutions will only increase. Professional adhesive enterprises like Guangdong Huachuang Electronic Materials Co., Ltd. are committed to meeting these demands through continuous innovation and improvement. Manufacturers can rely on these enterprises to provide cutting-edge epoxy resin potting compounds that meet industry standards for performance, reliability, and environmental sustainability, ensuring the success of their electronic devices.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments