Epoxy adhesive

Understanding Epoxy Resin Potting Compounds: A Comprehensive Guide

Understanding Epoxy Resin Potting Compounds: A Comprehensive Guide

Introduction:

Epoxy Resin potting compounds play a crucial role in the protection and encapsulation of electronic components. These compounds are widely used in various industries, including electronics, automotive, aerospace, and more. In this comprehensive guide, we will delve into the world of Epoxy Resin Potting compounds, exploring their applications, advantages, and the key factors to consider when selecting the right material for your specific needs.

1. What are Epoxy Resin Potting Compounds?

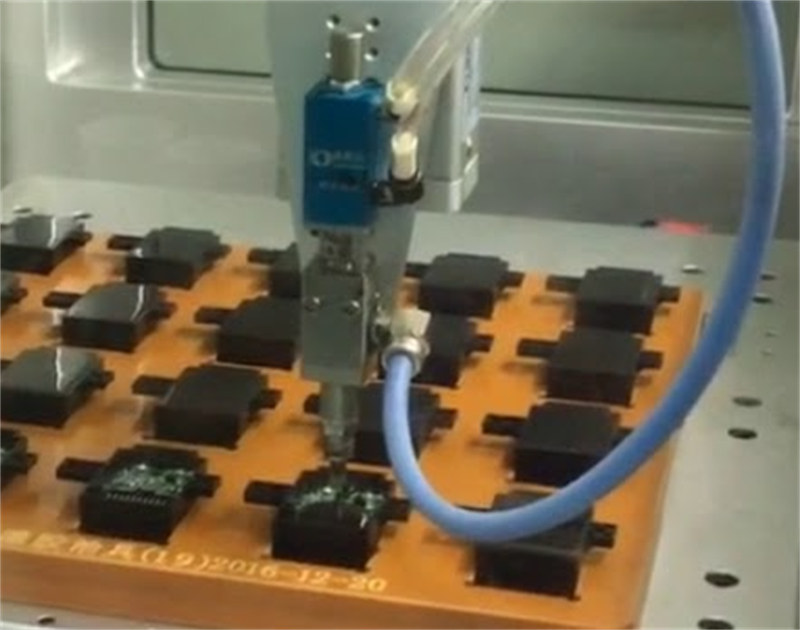

Epoxy resin potting compounds are two-part adhesives that consist of a resin and a hardener. When mixed together, they undergo a chemical reaction known as curing, resulting in a strong and durable material. These compounds are designed to encapsulate electronic components, providing protection against moisture, vibrations, and other environmental factors.

2. Advantages of Epoxy Resin Potting Compounds:

- Excellent adhesion: Epoxy resin potting compounds adhere well to various substrates, including metals, plastics, and ceramics.

- Thermal conductivity: Some Epoxy resin potting compounds have high thermal conductivity, allowing for efficient heat dissipation from electronic components.

- Chemical resistance: Epoxy resin potting compounds offer resistance to chemicals, such as solvents, acids, and bases, ensuring the longevity of the encapsulated components.

- Electrical insulation: These compounds provide excellent electrical insulation properties, protecting the components from short circuits and electrical failures.

- Mechanical strength: Epoxy resin potting compounds offer high mechanical strength, ensuring the integrity of the encapsulated components even in demanding conditions.

3. Applications of Epoxy Resin Potting Compounds:

- Electronics: Epoxy resin potting compounds are extensively used in the electronics industry for encapsulating and protecting printed circuit boards (PCBs), semiconductors, sensors, and other electronic components.

- Automotive: These compounds find applications in automotive electronics, such as engine control units (ECUs), sensors, and lighting systems, providing protection against vibrations, moisture, and temperature fluctuations.

- Aerospace: Epoxy resin potting compounds are crucial in aerospace applications, where they protect electronic components from extreme temperatures, pressure differentials, and vibrations.

- Renewable energy: They are used in the encapsulation of solar panels, wind turbines, and energy storage systems, ensuring long-term durability and reliability.

- Industrial equipment: Epoxy resin potting compounds find applications in various industrial equipment, such as motor drives, power supplies, and control systems, protecting them from harsh operating conditions.

4. Factors to Consider When Selecting Epoxy Resin Potting Compounds:

- Operating environment: Consider the temperature range, humidity levels, and exposure to chemicals or other harsh conditions when selecting the appropriate epoxy resin potting compound.

- Curing time: Different epoxy resin potting compounds have varying curing times. Consider the production requirements and the desired cycle time when choosing the compound.

- Thermal conductivity: If efficient heat dissipation is critical, select a compound with high thermal conductivity to ensure proper cooling of the encapsulated components.

- Electrical properties: Consider the dielectric strength, insulation resistance, and other electrical properties required for the specific application.

- Compatibility with substrates: Ensure that the epoxy resin potting compound is compatible with the materials being encapsulated to achieve optimal adhesion and performance.

Conclusion:

Epoxy resin potting compounds offer numerous advantages in the protection and encapsulation of electronic components. Their excellent adhesion, thermal conductivity, chemical resistance, and electrical insulation properties make them a popular choice across various industries. When selecting the right epoxy resin potting compound, factors such as the operating environment, curing time, thermal conductivity, electrical properties, and substrate compatibility should be considered.

About Guangdong Huachuang Electronic Materials Co., Ltd.:

Guangdong Huachuang Electronic Materials Co., Ltd. is a professional adhesive/new material R&D and production enterprise founded in 1999. With years of experience, the company specializes in the development and production of high-quality epoxy resin potting compounds. Their products are widely used in the electronics, automotive, aerospace, and renewable energy industries, providing reliable protection and encapsulation for electronic components. With a commitment to innovation and quality, Guangdong Huachuang Electronic Materials Co., Ltd. is a trusted partner in the field of epoxy resin potting compounds.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments