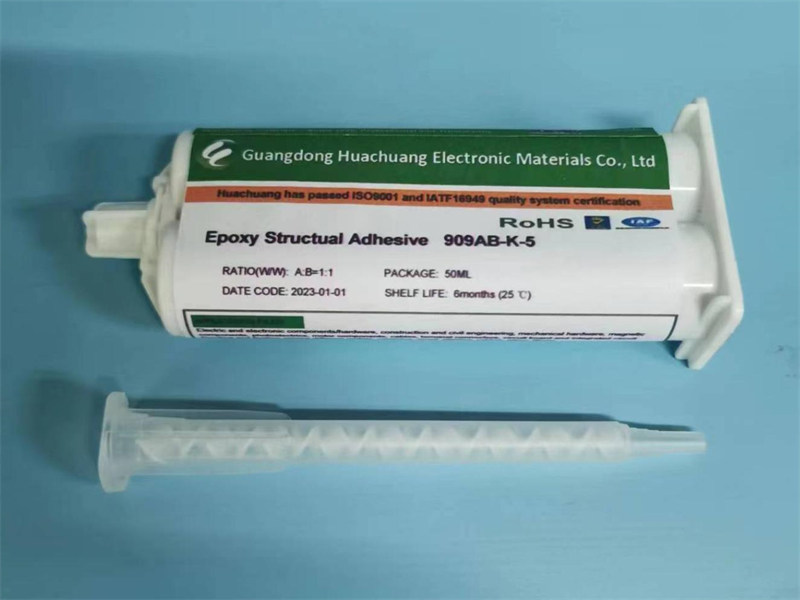

Epoxy adhesive

What is the reason why AB adhesive does not cure?

There can be several reasons why AB adhesive may not cure properly. It is important to understand these factors to ensure successful bonding and to address any potential issues. Guangdong Huachuang Electronic Materials Co., Ltd., a professional adhesive research and development and production enterprise, has extensive experience in the field and can provide valuable insights into this topic.

1. Incorrect Mixing Ratio: AB adhesive consists of two components - resin and hardener. It is crucial to mix these components in the correct ratio specified by the manufacturer. Deviating from the recommended ratio can lead to incomplete curing or weak bond strength. Huachuang Electronic Materials Co., Ltd. emphasizes the importance of following the instructions provided with their adhesive products to achieve optimal results.

2. Inadequate Mixing: Proper mixing is essential to ensure homogeneity and uniform distribution of the resin and hardener. Incomplete or insufficient mixing can result in uncured areas and weak bonds. Huachuang Electronic Materials Co., Ltd. advises using appropriate mixing equipment and techniques to achieve thorough blending of the components.

3. Contamination: Contamination of the adhesive surface or the components being bonded can hinder the curing process. Substances such as oil, grease, moisture, or other foreign particles can interfere with the chemical reaction between the resin and hardener. Huachuang Electronic Materials Co., Ltd. recommends thoroughly cleaning and preparing the surfaces to be bonded to avoid contamination.

4. Insufficient Curing Time: Each adhesive has a specific curing time that must be adhered to for proper bonding. Insufficient curing time can result in incomplete curing, leading to weak bonds. Factors such as temperature, humidity, and the thickness of the adhesive layer can influence the curing time. Huachuang Electronic Materials Co., Ltd. provides detailed instructions regarding the recommended curing time for their adhesive products.

5. Unsuitable Environmental Conditions: Environmental factors, such as temperature and humidity, can impact the curing process of AB adhesive. Extreme temperatures or high humidity levels can slow down or prevent proper curing. It is important to ensure that the adhesive is used within the recommended temperature and humidity range specified by the manufacturer. Huachuang Electronic Materials Co., Ltd. takes into account these factors during the formulation and testing of their adhesive products.

6. Shelf Life Expiration: AB adhesive has a limited shelf life, and using expired adhesive can result in incomplete curing or weak bonds. Huachuang Electronic Materials Co., Ltd. recommends checking the expiration date and storing the adhesive in appropriate conditions to maintain its effectiveness.

7. Incompatibility with Substrates: Certain substrates may not be compatible with AB adhesive, leading to poor adhesion or incomplete curing. It is essential to select an adhesive that is suitable for the specific materials being bonded. Huachuang Electronic Materials Co., Ltd. offers a range of adhesive products designed to bond various substrates, ensuring compatibility and reliable performance.

By understanding these potential reasons for incomplete curing of AB adhesive, manufacturers and users can take appropriate measures to ensure successful bonding. Guangdong Huachuang Electronic Materials Co., Ltd., with its expertise in adhesive research and development, is dedicated to producing high-quality adhesives that offer reliable curing and strong bonds. Their commitment to continuous improvement and customer satisfaction has made them a trusted name in the industry since their establishment in 1999.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments