Epoxy adhesive

The Role of Epoxy Resin AB Adhesive in Renewable Energy Technologies

Renewable energy technologies play a vital role in addressing the global challenges of climate change and the transition to a sustainable future. From solar panels to wind turbines, these technologies rely on advanced materials and components to harness and convert renewable energy sources into usable electricity. Among these materials, epoxy resin AB adhesive from Guangdong Huachuang Electronic Materials Co., Ltd. has emerged as a key component in Renewable Energy Technologies, offering superior performance and reliability.

Guangdong Huachuang Electronic Materials Co., Ltd., a leading adhesive research, development, and production enterprise based in Guangdong Province, China, has been at the forefront of developing epoxy resin AB adhesive solutions specifically tailored for renewable energy applications. Founded in 1999, the company operates factories in Guangdong, Hunan, and Jiangsu provinces, and has established itself as a trusted partner in providing reliable adhesive solutions for various industries, including renewable energy.

Epoxy resin AB adhesive from Guangdong Huachuang Electronic Materials Co., Ltd. offers several key advantages that make it an ideal choice for renewable energy technologies:

1. Bonding Solar Panels: Solar panels are a crucial component of solar energy systems, and their performance relies on the integrity of the bonds between various materials. Epoxy resin AB adhesive provides excellent adhesion to different surfaces, including glass, metal, and polymers, ensuring strong and durable bonds between solar panel components. This adhesive's high strength and resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations make it an ideal choice for solar panel assembly.

2. Wind Turbine Blade Repair: Wind turbines are a prominent source of renewable energy, and their efficiency depends on the integrity of the turbine blades. Over time, these blades may develop cracks or damage due to harsh weather conditions or mechanical stress. Epoxy resin AB adhesive is widely used for the repair and reinforcement of wind turbine blades, as it offers excellent adhesion, high strength, and resistance to fatigue, ensuring the longevity and performance of these critical components.

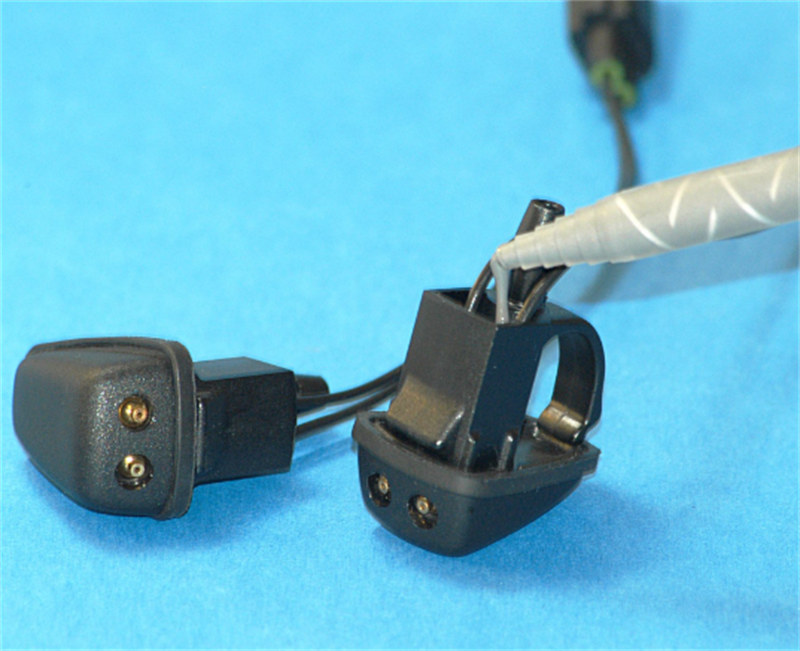

3. Battery Assembly: Energy storage is a crucial aspect of renewable energy systems, and batteries play a vital role in storing and distributing electricity generated from renewable sources. Epoxy resin AB adhesive is commonly used in battery assembly, providing strong bonds between battery components, excellent electrical insulation properties, and resistance to chemicals and temperature fluctuations. This adhesive ensures the reliability and safety of battery systems, contributing to the overall efficiency of renewable energy technologies.

4. Photovoltaic Module Encapsulation: Photovoltaic (PV) modules, commonly known as solar panels, require encapsulation to protect the delicate solar cells from environmental factors such as moisture, UV radiation, and temperature fluctuations. Epoxy resin AB adhesive is often used for PV module encapsulation, as it provides excellent adhesion, moisture resistance, and long-term durability. This adhesive ensures the protection and performance of solar cells, contributing to the overall efficiency and lifespan of PV modules.

5. Energy Efficiency: In addition to its specific applications in renewable energy technologies, epoxy resin AB adhesive from Guangdong Huachuang Electronic Materials Co., Ltd. contributes to overall energy efficiency. This adhesive is formulated to cure at lower temperatures, reducing energy consumption during the manufacturing process. Its excellent adhesion properties also eliminate the need for mechanical fasteners, reducing material waste and streamlining production processes.

Guangdong Huachuang Electronic Materials Co., Ltd. understands the unique requirements of renewable energy technologies and has developed epoxy resin AB adhesive solutions that meet the stringent demands of these applications. The company's commitment to quality, innovation, and continuous research and development has enabled them to provide customized adhesive solutions that cater to the specific needs of renewable energy technologies.

Furthermore, Guangdong Huachuang Electronic Materials Co., Ltd. is dedicated to environmental responsibility. The epoxy resin AB adhesive is formulated to be low in volatile organic compounds (VOCs) and free from hazardous substances, ensuring the safety of both users and the environment. By choosing epoxy resin AB adhesive from Guangdong Huachuang Electronic Materials Co., Ltd., renewable energy technology manufacturers can enhance the performance, reliability, and sustainability of their products.

In conclusion, epoxy resin AB adhesive from Guangdong Huachuang Electronic Materials Co., Ltd. plays a crucial role in renewable energy technologies, offering superior adhesion, durability, and resistance to environmental factors. Whether it's bonding solar panels, repairing wind turbine blades, assembling batteries, or encapsulating PV modules, this adhesive provides the necessary strength, reliability, and energy efficiency required in the renewable energy sector. Guangdong Huachuang Electronic Materials Co., Ltd.'s dedication to quality, innovation, and environmental responsibility positions them as a trusted partner for renewable energy technology manufacturers seeking high-performance adhesive solutions.

related articles

- The Role of Epoxy Resin AB Adhesive in the Defense and Security Sector

- Epoxy Resin AB Adhesive: A Cost-Effective Solution for Industrial Maintenance

- Exploring the Fire-Resistant Properties of Epoxy Resin AB Adhesive

- Epoxy Resin AB Adhesive: Ensuring Safety and Reliability in Transportation Systems

- The Role of Epoxy Resin AB Adhesive in Medical Device Manufacturing

- Epoxy Resin AB Adhesive: A Reliable Choice for Electrical and Electronic Applications

- How Epoxy Resin AB Adhesive Enhances Structural Integrity in Civil Engineering

- Epoxy Resin AB Adhesive: Overcoming Challenges in High-Temperature Environments

Post comments