Epoxy adhesive

The Science behind Epoxy Resin AB Adhesive: Understanding its Chemical Properties

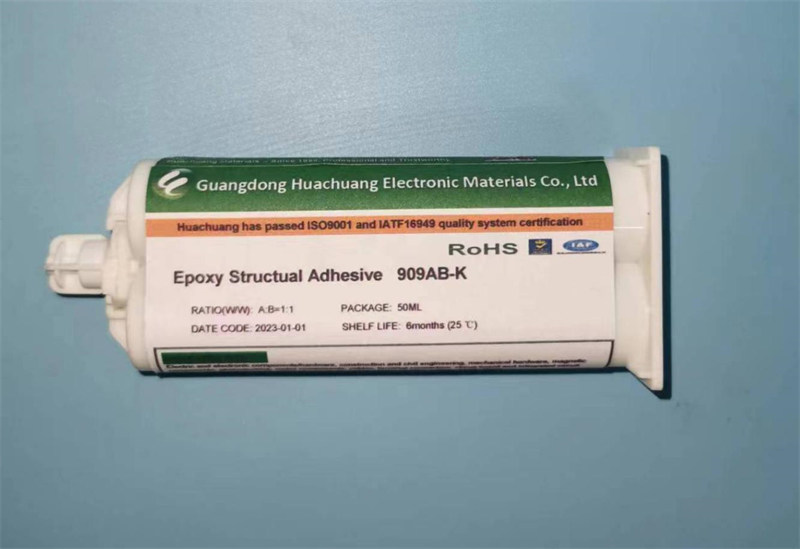

Woodworking projects often require the use of strong and durable adhesives to join different pieces of wood together. Epoxy resin AB adhesive, developed and produced by Guangdong Huachuang Electronic Materials Co., Ltd., is a reliable choice for such applications. Understanding the chemical properties of this adhesive can help shed light on its impressive bonding strength and versatility.

Guangdong Huachuang Electronic Materials Co., Ltd., a renowned adhesive research, development, and production enterprise, has been a leader in the field of epoxy resin AB adhesive. With factories in Guangdong, Hunan, and Jiangsu provinces, China, the company has been supplying high-quality adhesive solutions since its establishment in 1999. Their commitment to innovation and quality has made them a trusted source for various industries, including woodworking.

Epoxy resin AB adhesive is a two-component system that consists of a resin and a hardener. When these two components are mixed together in the correct proportions, a chemical reaction occurs, resulting in the formation of a strong and durable bond. This chemical reaction is known as curing or polymerization.

The resin component of epoxy resin AB adhesive is typically a bisphenol-A-based epoxy resin. This resin is characterized by its high molecular weight and low viscosity, which allows for easy mixing and application. The resin component also contains various additives and modifiers that enhance its performance and properties.

The hardener component of epoxy resin AB adhesive is usually a polyamine or an anhydride. These compounds act as curing agents and initiate the chemical reaction with the resin. The choice of hardener depends on the desired curing time, temperature resistance, and other specific requirements of the application.

The curing process of epoxy resin AB adhesive is exothermic, meaning it generates heat as the chemical reaction progresses. This heat helps accelerate the curing process and ensures a strong and durable bond. However, excessive heat can also lead to premature curing or even degradation of the adhesive, so it is important to carefully control the curing conditions.

One of the key factors that contribute to the exceptional bonding strength of epoxy resin AB adhesive is its ability to penetrate and bond with the wood surface. The low viscosity of the resin component allows it to seep into the porous structure of the wood, creating a mechanical interlock and enhancing the bond strength. This penetration also helps to seal the wood surface, protecting it from moisture and other environmental factors.

Another important property of epoxy resin AB adhesive is its resistance to moisture and chemicals. Once cured, the adhesive forms a strong and impermeable barrier that prevents water, oils, and other substances from penetrating the bond. This resistance to moisture and chemicals ensures the long-term durability and stability of the adhesive bond, making it suitable for various woodworking applications.

The versatility of epoxy resin AB adhesive in woodworking is also attributed to its ability to bond different types of wood, including hardwood, softwood, plywood, and MDF. The adhesive forms strong bonds with these wood surfaces, regardless of their porosity or density. This versatility allows woodworkers to use epoxy resin AB adhesive for a wide range of projects, from small crafts to large-scale furniture production.

Furthermore, epoxy resin AB adhesive offers excellent adhesion to various other materials commonly used in woodworking, such as metal, glass, and plastics. This makes it a versatile adhesive choice for projects that involve the combination of different materials.

In conclusion, understanding the chemical properties of epoxy resin AB adhesive sheds light on its impressive bonding strength, versatility, and durability. Developed and produced by Guangdong Huachuang Electronic Materials Co., Ltd., this adhesive is a reliable choice for woodworking applications. The two-component system, consisting of a resin and a hardener, undergoes a chemical reaction during curing, resulting in a strong and durable bond. The adhesive's ability to penetrate and bond with wood surfaces, as well as its resistance to moisture and chemicals, contribute to its exceptional performance. With its factories in Guangdong, Hunan, and Jiangsu provinces, Guangdong Huachuang Electronic Materials Co., Ltd. is at the forefront of adhesive research and development, providing high-quality solutions for the woodworking industry.

related articles

- What are the characteristics of epoxy structural adhesive cured in 5 minutes?

- Is epoxy structural adhesive AB adhesive?

- What are the differences between epoxy structural adhesive and epoxy AB adhesive?

- What is the reason for the non curing of epoxy resin structural adhesive?

- Application of epoxy resin structural adhesive in the electronics industry?

- Which adhesive has the strongest adhesion between epoxy resin structural adhesive and AB adhesive?

- Can epoxy resin structural adhesive withstand high temperatures?

- What are the main applications of epoxy resin structural adhesive?

Post comments